How to Pack a Cooler for Maximum Ice Retention?

A lukewarm drink or a soggy sandwich can ruin even the best outdoor trip—and it all comes down to how you pack your cooler. Get it right, and ice stays solid for days, keeping food fresh and drinks frosty. Get it wrong, and you’ll be stuck with slush by noon.

This […]

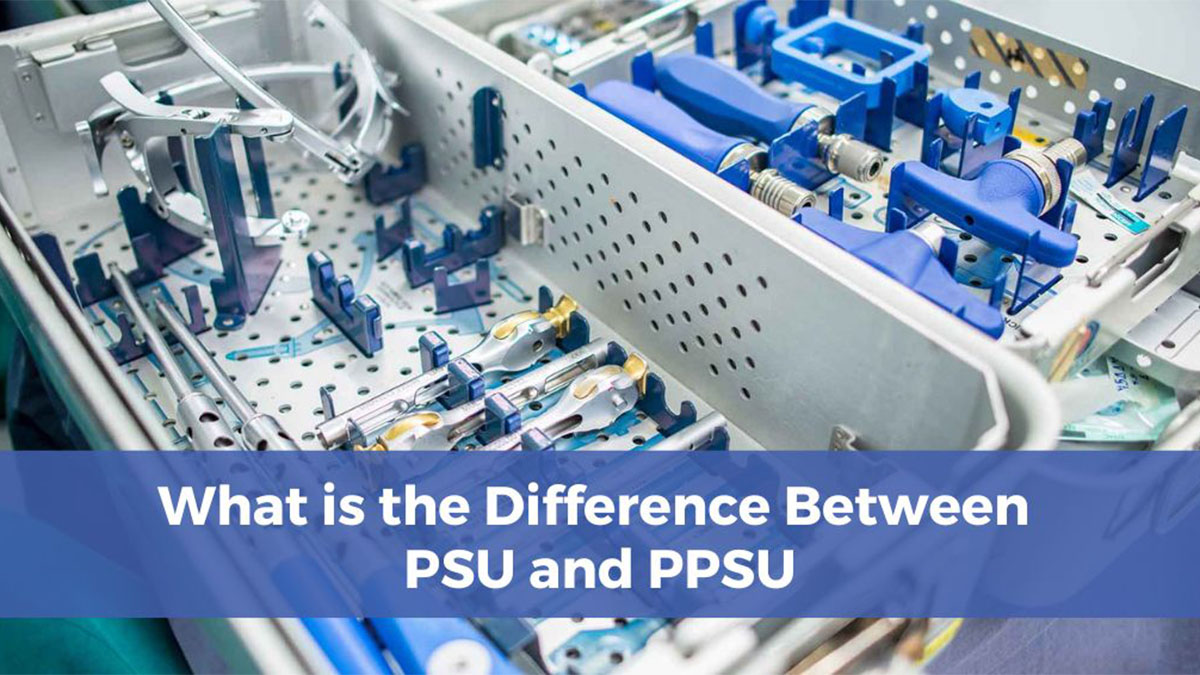

Polyphenylene sulfone (PPSU) and polysulfone (PSU) belong to the sulfone class of amorphous high-performance polymers. With excellent biocompatibility, heat resistance, and chemical stability, they have always been the core [...]

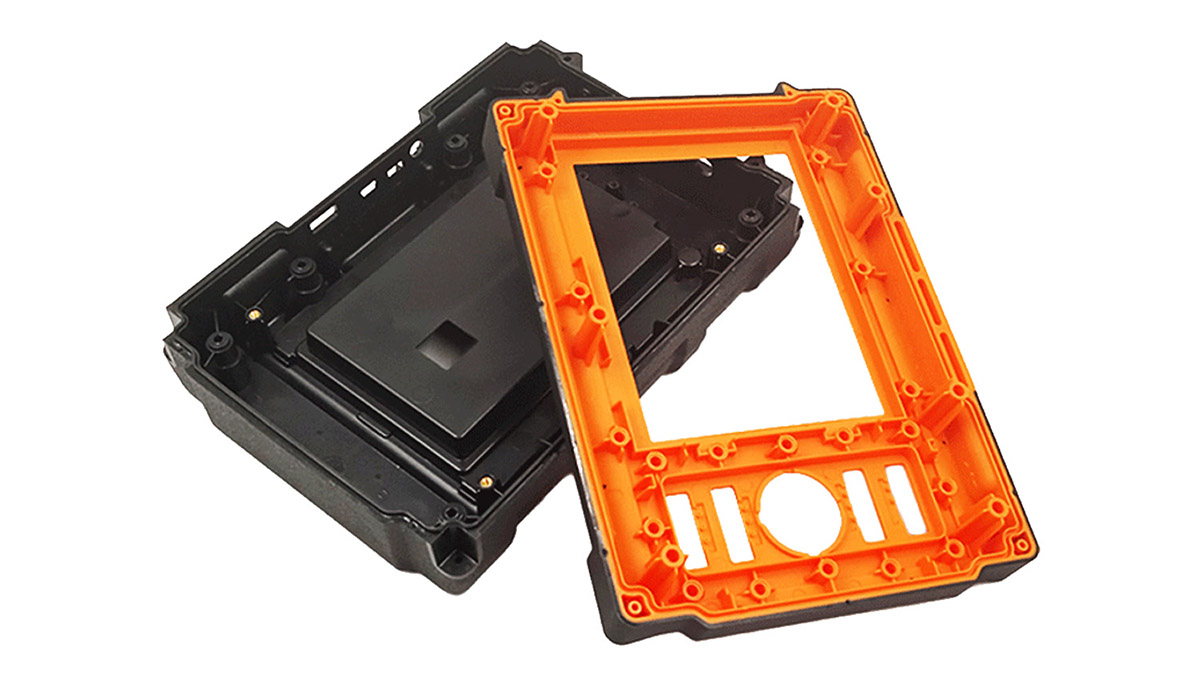

Two color plastic products have a wide range of applications in people’s daily lives and industrial production, such as two-color toothbrush handles, pen holders, and toy case. They all [...]

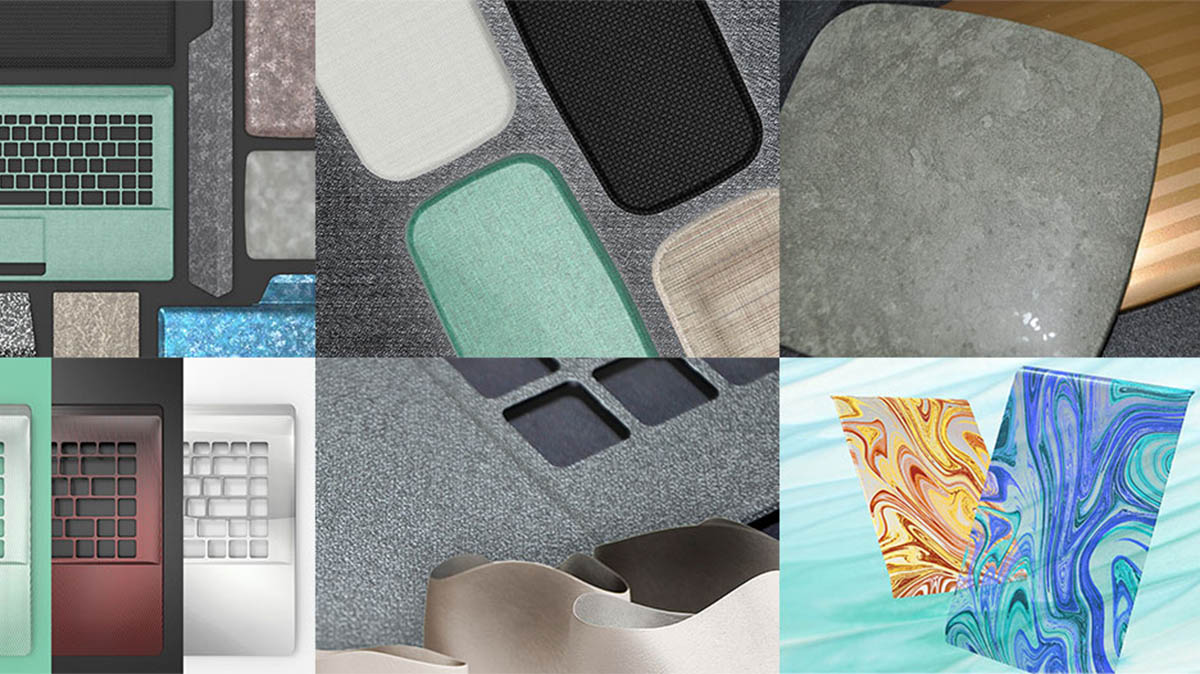

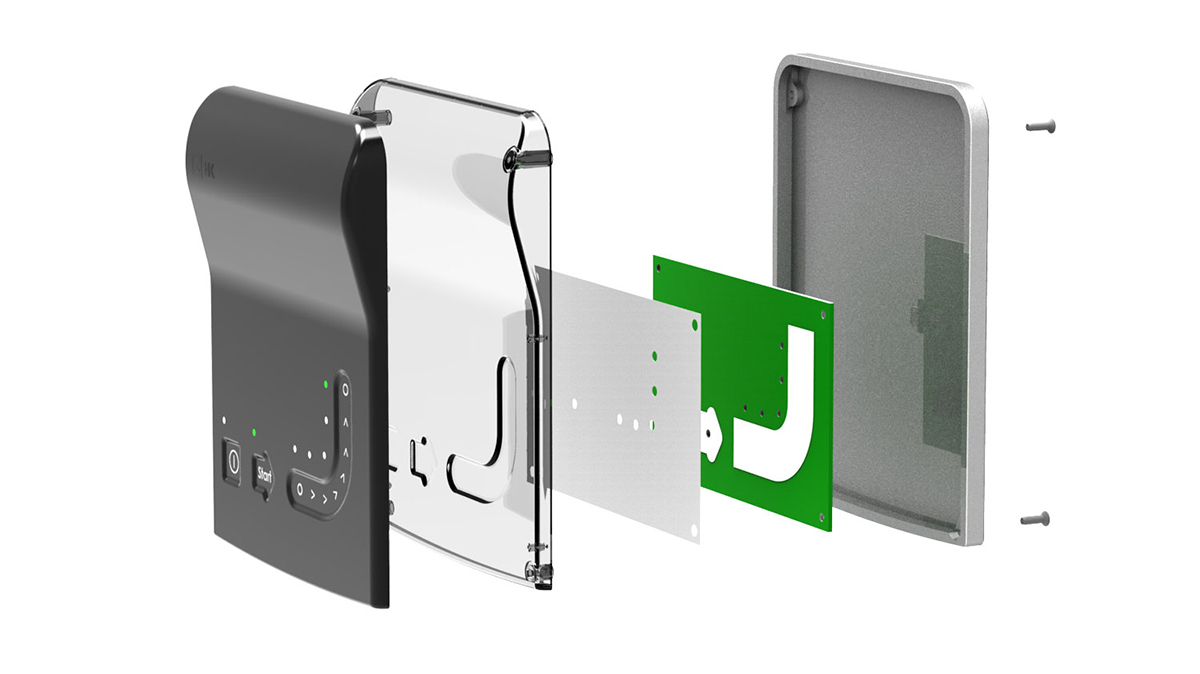

Nowadays, industries such as consumer electronics and home appliances are pursuing products that are “light, thin, and short”, and also value appearance, texture, and environmental friendliness. Traditional processes such [...]

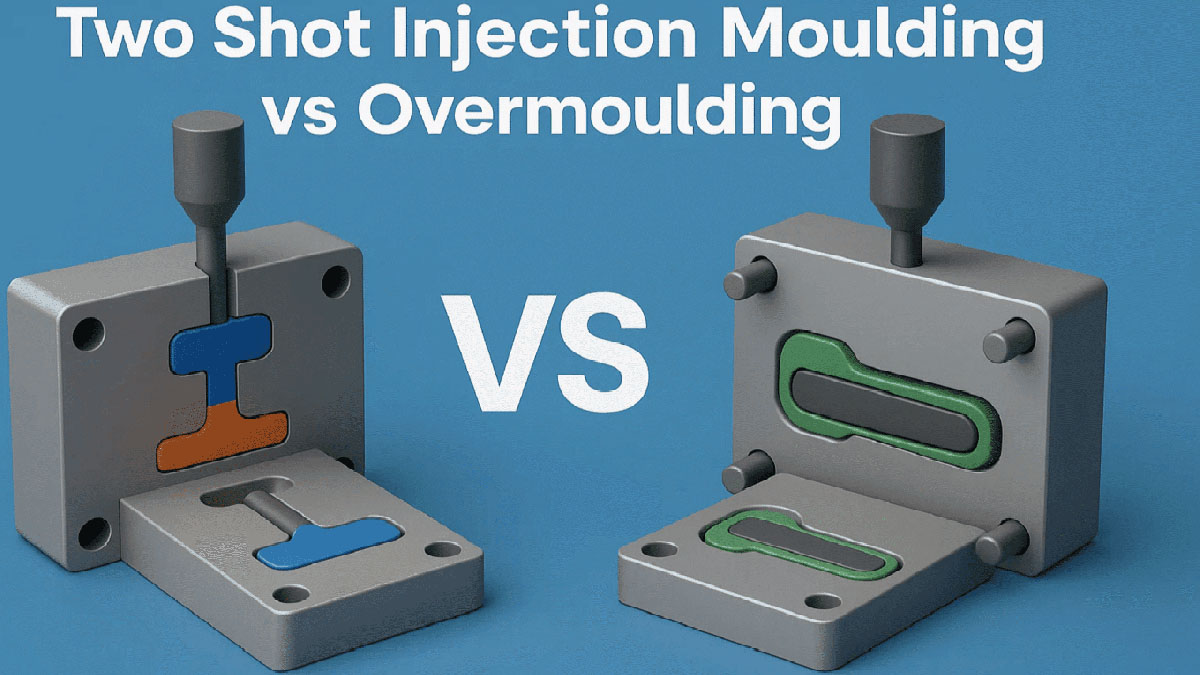

In the field of plastic product manufacturing, two-shot injection molding and overmolding are two mainstream multi-material molding processes. With their unique technical characteristics and application advantages, they serve diverse [...]

TPU (Thermoplastic Polyurethane) is widely used in many industries due to its excellent elasticity, wear resistance, oil resistance, and other properties. Molding is the core method of TPU processing, [...]

The shrinkage rate of plastics directly relates to the shape and dimensional accuracy of the product. The characteristics of plastic products, mold design, process condition control, and other factors [...]

Professionals in the 3C electronics, automotive interior, or smart home industries have most likely encountered this issue: in order to give the product a special texture (such as walnut [...]

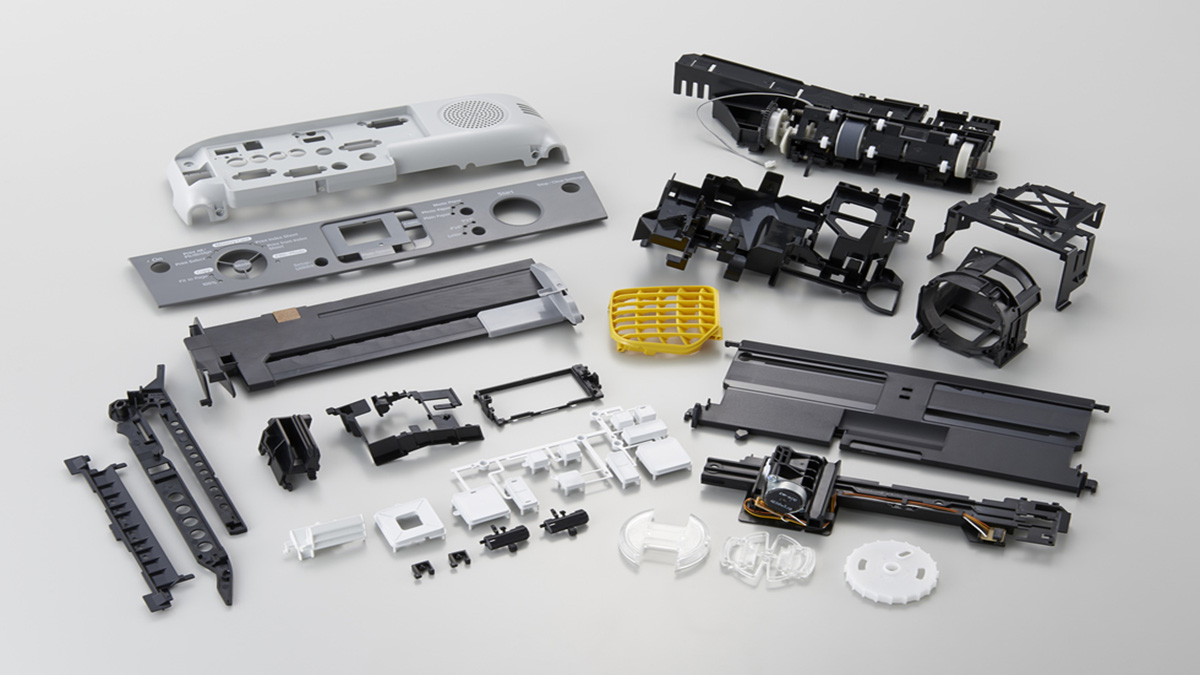

With the rapid development of technology, plastic parts have become widely used in various fields of daily life and industrial production due to their lightweight, low cost, and easy [...]

Under the trend of upgrading plastic products towards multifunctionality, high aesthetics, and integration, two-shot injection molding technology has become a key molding technology in fields such as automotive interiors, [...]

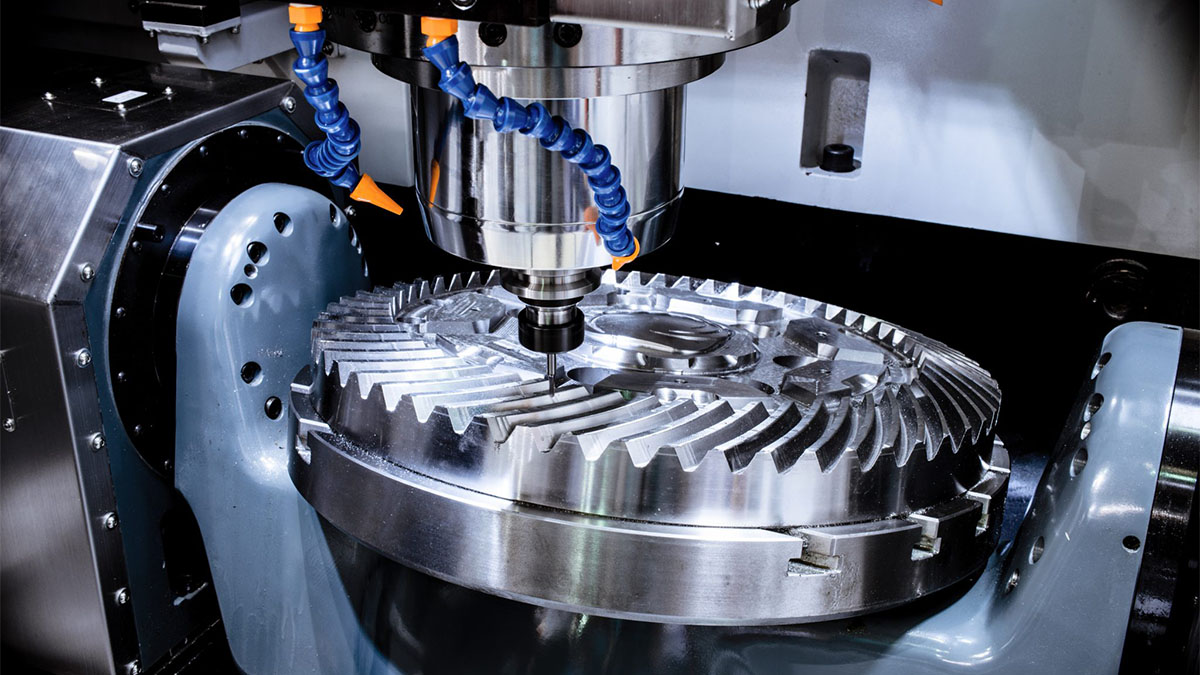

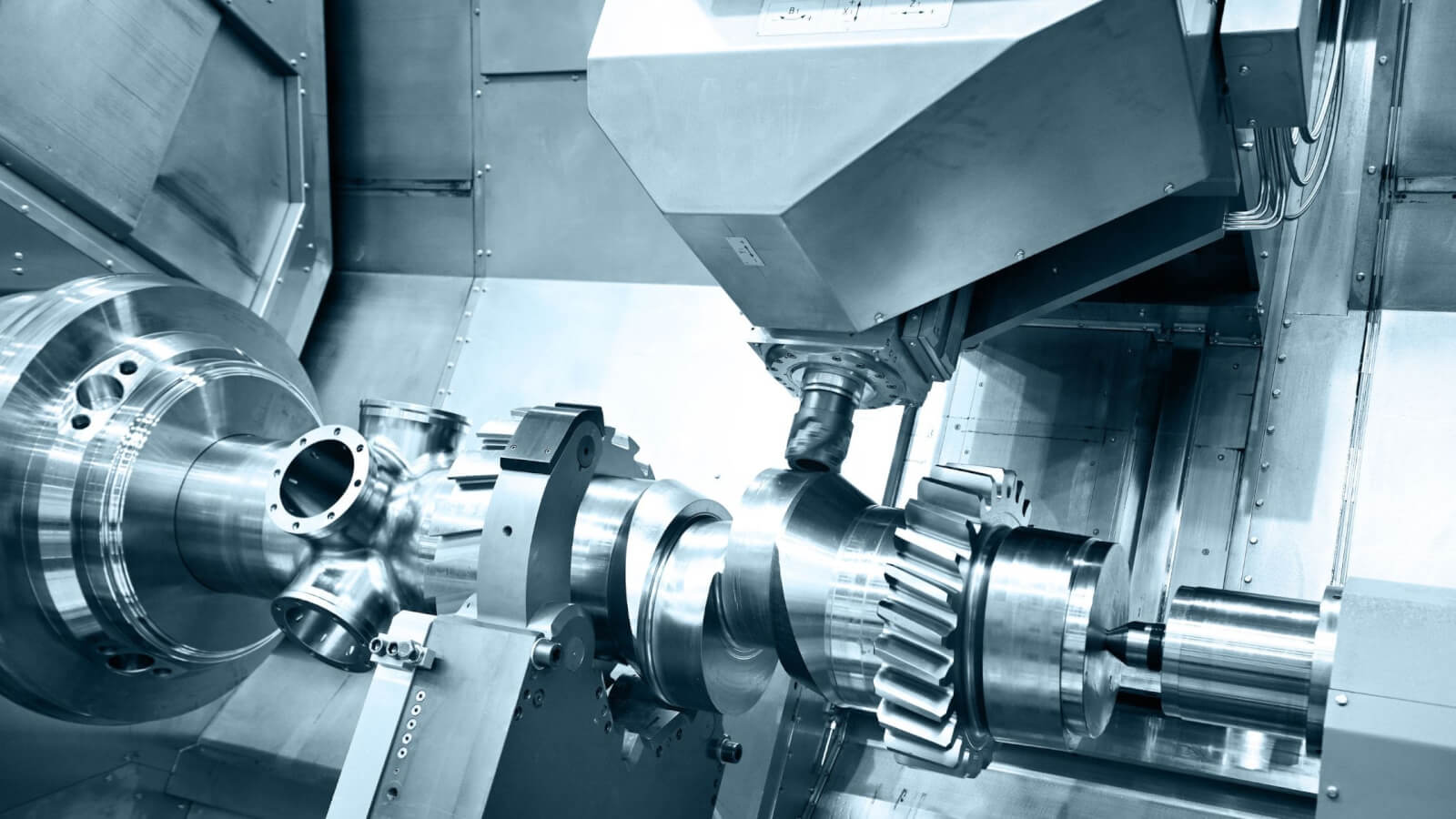

In the field of CNC machining, standardization is the core support for ensuring production safety, controlling product accuracy, and improving operational efficiency. In order to effectively avoid machining risks, [...]

Many beginners who are just getting started with CNC machining often fall into a trap: they blindly memorize the terms like "milling / turning" and "three-axis / five-axis", but [...]

Polyphenylene sulfone (PPSU) and polysulfone (PSU) belong to the sulfone class of amorphous high-performance polymers. With excellent biocompatibility, heat resistance, and chemical stability, they have always been the core [...]

The shrinkage rate of plastics directly relates to the shape and dimensional accuracy of the product. The characteristics of plastic products, mold design, process condition control, and other factors [...]

With the rapid development of technology, plastic parts have become widely used in various fields of daily life and industrial production due to their lightweight, low cost, and easy [...]

In the injection molding industry now, everyone is leaning towards high-quality, personalized products, and environmentally friendly production. However, traditional decoration techniques such as spray painting and electroplating are really [...]

What is the Difference Between PLA/PHA VS PBS/PBAT? Can KingStar Mold produce parts and complete products using injection molding technology and PLA/PHA/PBS/PBAT raw materials? These are questions that customers [...]

In the fields of precision manufacturing such as home appliance panels and vehicle exterior panels, AL5052 aluminum sheet stamped parts have become the core components due to their excellent [...]

In modern manufacturing, thermoplastic injection molding technology, with its advantages of efficient mass production and controllable precision, can stably produce complex shaped components. In addition, the material itself has [...]

In current industrial production, thin-wall injection molding materials are widely used in various fields such as packaging and electronics due to their unique advantages. From daily food packaging to [...]

Plastic storage boxes have become indispensable for both daily life and industrial use, and their quality and performance depend heavily on the materials they’re made of. Different types of [...]

The quality of injection molded products is the cornerstone for enterprises to establish themselves in the market, and quality managers are the core guardians of this quality defense line. [...]

In the field of CNC machining, standardization is the core support for ensuring production safety, controlling product accuracy, and improving operational efficiency. In order to effectively avoid machining risks, [...]

Plastics have become fundamental components in contemporary life, serving critical functions in nearly every sector from healthcare to consumer goods. Their ubiquitous nature demands rigorous quality assurance measures to [...]

This plastic parts inspection specification applies to all plastic components produced by KingStar Mold, including those made through injection molding, as well as externally sourced plastic accessories and products [...]

Whether the overmolding mold is qualified is crucial, as the design of the mold structure and the mold fitting(FIT) process during manufacturing are extremely important. All personnel involved in [...]

If you’ve ever shopped for a high-performance cooler, you’ve probably noticed Yeti coolers' price tag stands out—and for good reason. These coolers have built a reputation for lasting through [...]

Many beginners who are just getting started with CNC machining often fall into a trap: they blindly memorize the terms like "milling / turning" and "three-axis / five-axis", but [...]

TPU is an elastomer and is widely applied in two-color injection molding process. Bayer TPU possesses excellent physical properties and is characterized by targeted development. In other words, it [...]

TPU (Thermoplastic Polyurethane Elastomer), with its outstanding wear resistance, elasticity and weather resistance, is widely used in automotive, electronic, medical, packaging and other fields. However, different types of TPU [...]

For manufacturers and engineers working with products made through PVC injection molding(especially wire and cable compounds, flexible films, and consumer goods) choosing the right plasticizer is critical to achieving [...]

If you are engaged in an industry related to the manufacturing of plastic products (injection molding, 3D printing, etc.), then you are likely to have encountered a common problem: [...]

Whether you’re an R&D engineer refining plastic blends for injection molding, a QA specialist checking consistency in silicone rubber molding parts, or a procurement pro verifying material specs, Shore [...]

Whether you’re gearing up for a weekend camping trip, a backyard BBQ, or a long road trip, a cooler is your best friend for keeping food fresh and drinks [...]

Polyphenylene sulfone (PPSU) and polysulfone (PSU) belong to the sulfone class of amorphous high-performance polymers. With excellent biocompatibility, heat resistance, and chemical stability, they have always been the core [...]

If you’ve spent any time in the outdoor community, you know Yeti is the "Tesla" of the cooler world. But as you browse our latest Igloo Hard Cooler Collection, [...]

Two color plastic products have a wide range of applications in people’s daily lives and industrial production, such as two-color toothbrush handles, pen holders, and toy case. They all [...]

At the finish line of a marathon, on a hot construction site, or in the backyard of a family gathering, a signature Igloo Sports Cooler is often the center [...]

Nowadays, industries such as consumer electronics and home appliances are pursuing products that are “light, thin, and short”, and also value appearance, texture, and environmental friendliness. Traditional processes such [...]

In the field of plastic product manufacturing, two-shot injection molding and overmolding are two mainstream multi-material molding processes. With their unique technical characteristics and application advantages, they serve diverse [...]

TPU (Thermoplastic Polyurethane) is widely used in many industries due to its excellent elasticity, wear resistance, oil resistance, and other properties. Molding is the core method of TPU processing, [...]

The shrinkage rate of plastics directly relates to the shape and dimensional accuracy of the product. The characteristics of plastic products, mold design, process condition control, and other factors [...]

When traveling outdoors, a reliable hard cooler box is essential for the happiness of the journey - whether it’s cold beer, fresh ingredients, or medicines that require low-temperature preservation, [...]

Dear customers: Considering the national statutory holiday schedule and the actual situation of our company, our company will start the Chinese New Year holiday on January 28, 2025 (Tuesday), [...]

The Yangtze River Delta region has become the most intensive area for plastic processing industry, and Jiangsu Province accounts for more than 40% of the output Thanks to multiple [...]

Against the backdrop of the global wave of “plastic limitation and ban” policies, such as the EU Single-Use Plastics Directive and China’s “Plastic Reduction 2.0,” the injection molding industry [...]

At KingStar Mold, our commitment goes far beyond high-quality manufacturing. We firmly believe that being an integral part of the community is at the core of our identity. Over [...]