Plastic Injection Molding Company for Baby Products

Orders Workflow

Initial Consultation & Design Review

We begin by discussing your project’s goals and reviewing the design to ensure it’s optimized for the specific manufacturing process. At this stage, we suggest improvements or adjustments to enhance efficiency, functionality, and manufacturability.

Material Selection

Our experts assist in selecting the right materials for your product based on performance requirements and compatibility with the manufacturing process. The correct material choice ensures durability, cost-effectiveness, and the desired product functionality.

Design & Engineering

Using advanced CAD and simulation tools, we develop a custom design for your project. This step ensures precise details and identifies potential challenges early in the process, optimizing the design for efficient manufacturing.

Prototyping & Sample Testing

A prototype or sample is created to verify design accuracy, functionality, and performance. Rigorous testing is conducted to ensure the product meets your specifications before moving into full-scale production.

Production Setup & Initial Production

We set up the required machines, molds, or tools for the manufacturing process. The initial production run is performed to confirm the setup, assess quality, and fine-tune settings for optimal results.

Final Production & Quality Control

After final approval, we proceed with full-scale production, ensuring continuous quality checks. Comprehensive inspections at each stage ensure that every part meets the highest standards before delivery.

Our baby bath rinse cups are designed with a soft, ergonomic handle for easy grip and control. Made from high-quality, non-toxic PP plastic, they are gentle on your baby’s skin while being durable enough for everyday use. The cups are manufactured with precise molding techniques to ensure a smooth finish and leak-proof performance.

Crafted from durable ABS plastic, our baby bath tubs provide a safe and comfortable bathing experience for infants. They are designed with rounded edges and a slip-resistant base to prevent accidents. Our manufacturing process ensures the tubs are lightweight, easy to clean, and compliant with all safety standards.

These baby cleaning tweezers are perfect for picking up small items or cleaning delicate areas like baby’s ears or nose. Made from high-quality, BPA-free plastic, they are designed to be gentle yet precise. The manufacturing process involves rigorous quality control to ensure smooth tips and comfortable handling for parents.

Baby Bath Rinse Cup

Baby Bath Tub

Cleaning Tweezers

Our massaging baby teethers are designed to soothe sore gums with soft, textured surfaces that are safe for babies to chew on. Made from food-grade, non-toxic materials like silicone, they are durable and easy to clean. The manufacturing process ensures each teether is free from harmful chemicals and designed for maximum comfort and safety.

Neck bottles are ergonomically designed to help babies drink comfortably while minimizing spills. These bottles are made from high-quality, BPA-free polypropylene, ensuring safety and durability. The manufacturing process includes extensive testing to ensure each bottle is leak-proof and features anti-colic designs for a better feeding experience.

Our toddler swing seats are made with sturdy and safe materials like ABS plastic, designed for both indoor and outdoor use. They feature comfortable, secure harnesses to keep toddlers safe while enjoying a fun swing ride. The manufacturing process involves precise molding to ensure smooth edges, durability, and long-lasting safety.

Massaging Baby Teether

Neck Bottles

Toddler Swing Seat

Why Choose Injection Molding For Baby Products Manufacturing?

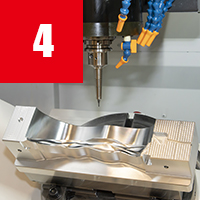

One key benefit of our injection molding technology is the rapid production of prototypes. By utilizing both 3D printers and CNC machines, we ensure your plastic baby product prototypes are created in the shortest time frame possible.

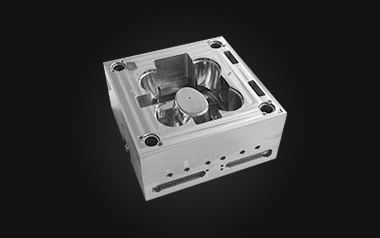

We take pride in being able to produce over 600 set molds in a year. This has garnered us a reputation for being able to fulfill any order, no matter how big it is. No matter how large the scale of the order, we are more than capable of fulfilling it.

KingStar Mold always adheres to a high standard of control. We follow the strictest quality control, and any plastic parts that we distribute, are tested by our specialized team of experts. Rest assured, any product you get from KingStar Mold is of the best quality possible.

By utilizing injection molding for your baby products, you are assured that you will be saving money. Just one injection mold could be used to create a myriad of parts. This means that you will save on both material and production costs.

Safe Plastic Materials for Baby Products

As babies develop stronger immunity over time, they remain highly vulnerable to toxicity and contaminants in product materials. For example, the presence of BPAs in thermoplastics used in toy injection molding has been linked to developmental disorders and an increased risk of cancer.

At KingStar Mold, we prioritize the well-being of our consumers. We are committed to using baby-safe polypropylene and other medically approved materials. Our production processes are carefully designed to preserve the integrity of these materials, ensuring they remain free of harmful side effects.

Previous Injection Molded Baby Product Projects

Yes, all our products are made with skin-safe, soft materials designed to be gentle on babies’ sensitive skin.

We implement thorough quality control throughout the manufacturing process, including material inspection, product testing, and compliance checks to guarantee top-quality products.

KingStar Mold ensures the safety of its products by adhering to strict safety standards, using non-toxic materials, and conducting rigorous testing.

Yes, we offer customization options for the design, color, and size of our baby products to meet your specific needs.

Yes, all of our baby products are BPA-free, ensuring they are safe for babies and meet international safety standards.

We use non-toxic, high-quality materials like PP (Polypropylene), ABS (Acrylonitrile Butadiene Styrene), and PVC to ensure safety and durability.

KingStar Mold offers high-quality, safe, and customizable baby products, backed by reliable manufacturing processes and a commitment to customer satisfaction.

Our baby products are easy to clean and maintain. Most can be washed with warm soapy water, while others are dishwasher safe for added convenience.

Yes, KingStar Mold produces eco-friendly baby products made from recyclable materials and adheres to sustainability practices in our manufacturing processes.

Our products are designed for newborns through toddlers, with age-appropriate features for each stage of development.

Lead time for custom baby products from KingStar Mold typically ranges from 2 to 4 weeks, depending on the complexity and order size.

KingStar Mold uses high-quality, durable materials and precise manufacturing techniques to ensure that our baby products stand the test of time and daily use.