Anodizing

Anodizing is an electrochemical surface treatment process mainly used for aluminum and aluminum alloy parts. By using the workpiece as the anode in an electrolyte solution, a controlled oxidation reaction occurs on the surface, resulting in a layer of oxide film (alumina film) that integrates with the base material. Unlike spraying or electroplating, this oxide layer is not simply attached to the surface but chemically combines with the metal substrate as a whole, thus having extremely high adhesion strength and stability.

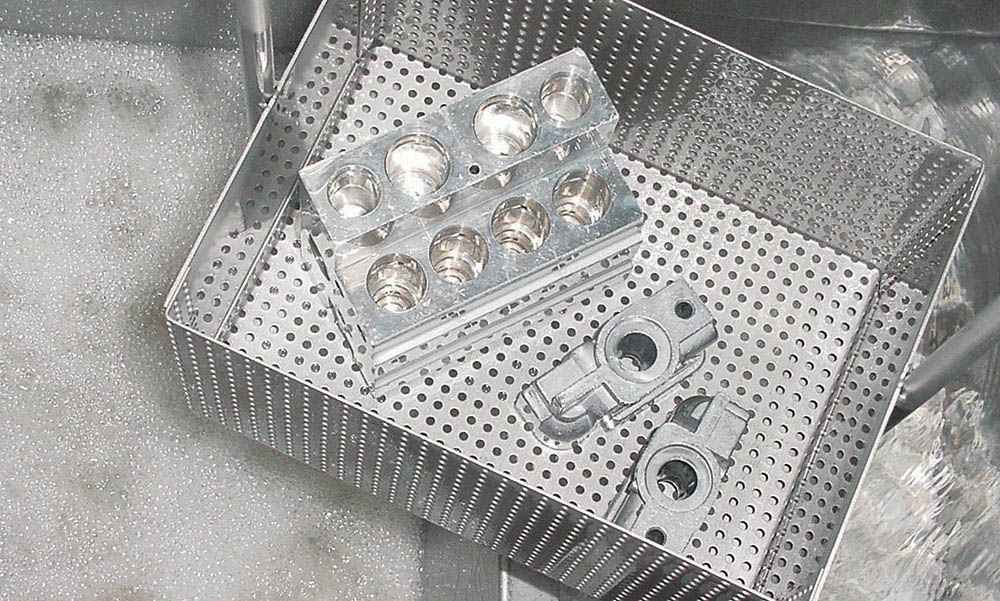

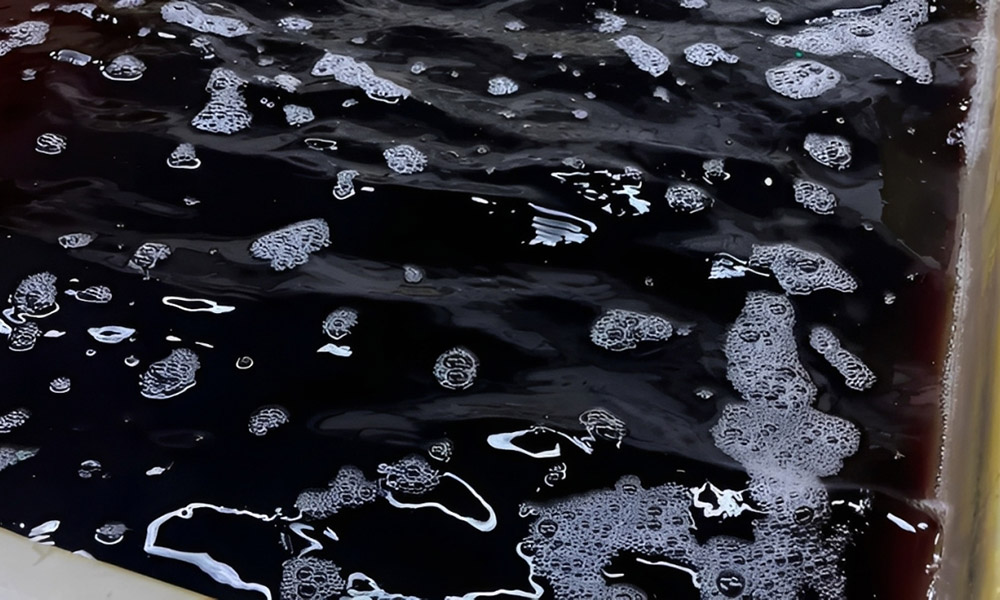

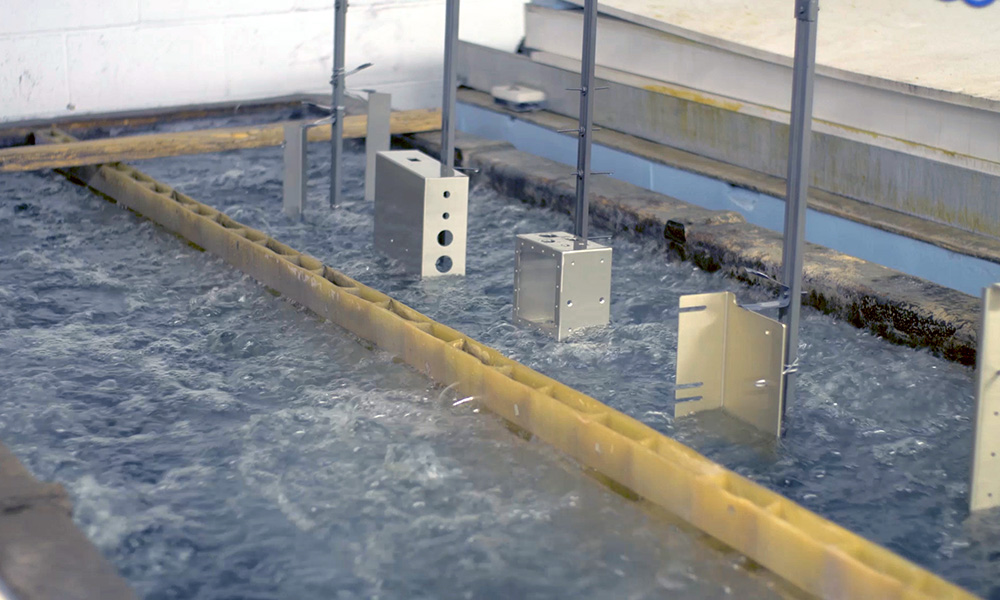

During the anodizing process, aluminum parts are immersed in an acidic electrolyte and electrically charged to become the anode. The current causes an oxidation reaction on the metal surface, resulting in a uniform layer of aluminum oxide. Before sealing the holes, this oxide layer has a microporous structure and can be used for coloring or improving adhesion; after sealing treatment, this layer of film will become denser and more durable.

The aluminum materials treated by anodizing have the following advantages: they have strong corrosion resistance, high surface hardness, strong color expression ability and good decorative properties, and can enhance the adhesion of subsequent coatings.

Our Most Requested Anodizing Services

Showcase of Anodizing Finished Products

Bike Chain Guide

Corner Bracket

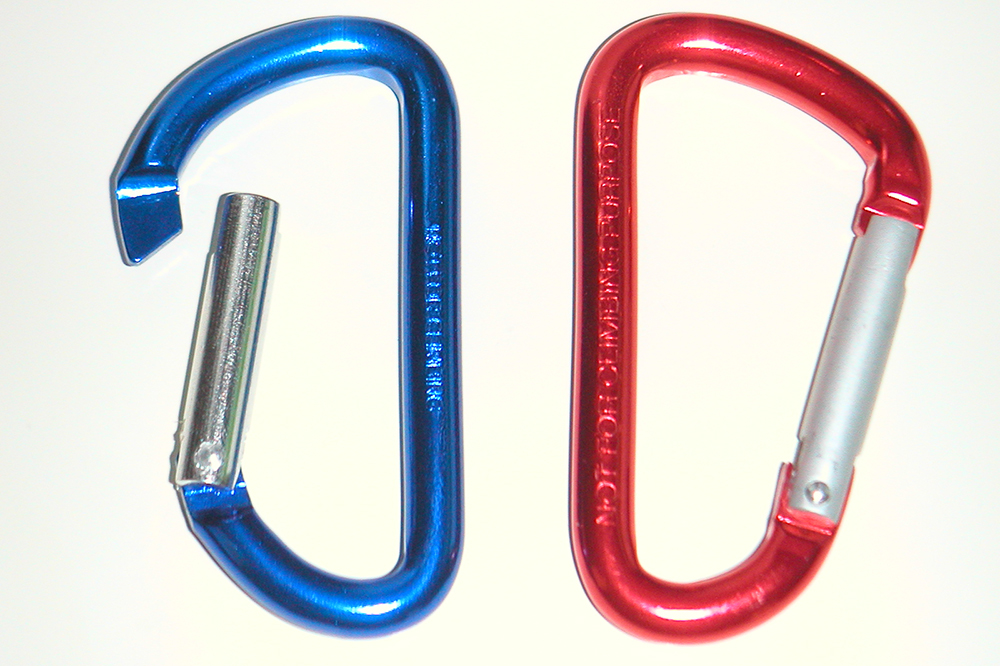

Carabiners

Hanger Rack

Adjustment Screws

Lock Nuts

Multi-flanged Plug

Flangeless Plug

Color Options for Anodizing

The anodizing process creates a porous oxide layer on the aluminum surface, making it possible to achieve rich and long-lasting colors. Coloring is mainly achieved through two methods: the dye impregnation method, where the oxidized components are immersed in organic or inorganic dyes to adsorb colors; and electrolytic coloring, where metal particles are deposited in the micropores through electrolysis to produce tones.

While Type I (Chromi c Acid) and Phosphoric Acid anodizing are important for specific aerospace or adhesion-promotion applications, they offer very limited or no decorative coloring capabilities and are thus not the focus of this color chart.

We offer a wide range of color options, from classic colors to custom colors, including champagne gold, titanium color and other special effects. These colors are not only aesthetically pleasing but also possess excellent resistance to fading and wear due to the sealing process, and can meet various needs ranging from precision instruments to fashionable consumer products.

Champagne

Gold

Black

Silver

Bronze

Blue

Red

Green

Purple

Titanium

| Color | Dye Immersion | Electrolytic Coloring | Suitable Process (Type) | Typical Industries & Applications |

|---|---|---|---|---|

| Champagne | Available (Common) | Available (Specific Alloy/Process) | Primarily Type II | High-end Consumer Goods, Architectural Hardware, Trim, Gifts |

| Gold | Available (Standard Yellow Dye) | Preferred (Better Durability) | Type II, Type III (Limited) | Architectural Trim, Luxury Accessories, Nameplates, Furniture |

| Black | Available (Standard) | Preferred (Deeper & Better Weathering) | Type II, Type III | Consumer Electronics Housings, Optical Devices, Automotive Parts, Industrial Components |

| Silver | N/A (Natural Color) | N/A (Natural Color) | Type II, Type III | Machinery, Aerospace Components, Minimalist Architectural Profiles |

| Bronze | Available (Bronze-like) | Preferred (Authentic Bronze Appearance) | Type II | Architectural Curtain Walls, Roofing, Decorative Art Pieces |

| Blue | Available | Generally Not Used | Type II | Sporting Goods, Signage, Medical Devices, Custom Consumer Products |

| Red | Available | Generally Not Used | Type II | Safety Equipment, Buttons, Musical Instruments, Branded Custom Parts |

| Green | Available | Generally Not Used | Type II | Instrument Panels, Military Equipment, Specialty Decor |

| Purple | Available | Generally Not Used | Type II | Personalized Consumer Electronics, Gifts, Fashion Accessories |

| Titanium | N/A | Primary Method (Interference Coloring) | Type II (Specific Process) | Eyewear Frames, Watches, High-end Trim with Titanium-like Finish |

| Custom | Primary Method (Custom Blending) | Limited (Dependent on Metallic Salts) | Type II | Brand-Specific Colors, Any Field with Unique Design Requirements |

Notes:

- This table focuses on Type II (Sulfuric Acid) Anodizing, the standard for coloring. Type III (Hardcoat) is suitable mainly for natural, black, and dark bronze shades due to its dense structure.

- Color Performance: Electrolytically colored parts (e.g., most golds, blacks, bronzes) generally offer superior UV resistance and colorfastness because the pigment consists of metallic particles.

- Other Processes: Type I (Chromi c Acid) anodizing is used in specialized fields (e.g., aerospace) with very limited color options. Phosphoric acid anodizing is a pretreatment for adhesion, not for decorative coloring.

- Custom Service: For custom colors, we primarily utilize the Dye Immersion method for precise color matching to meet your unique branding or design needs.

Our 9-Step Anodizing Workflow

Advantages of Anodizing Your Product

All Options Available for Anodizing

| Anodizing Type | Available Colors | Durable Time |

|---|---|---|

| Type I (Chromic Acid Anodizing) | Clear, Light Bronze, Gold, Gray | 5-10 years (depending on environment) |

| Type II (Sulfuric Acid Anodizing) | Black, Bronze, Blue, Red, Green, Gold | 10-20 years in outdoor conditions |

| Type III (Hard Anodizing) | Black, Gray, Bronze, Silver (mostly dark colors) | 20+ years (highly resistant to wear) |

| Type IV (Organic Acid Anodizing) | Clear, Metallic Sheen | 5-10 years (light applications) |

| Type V (Microporous Anodizing) | Clear, Light Shades | Moderate durability (for specific applications) |

| Titanium Anodizing | Blue, Purple, Gold, Bronze, Rainbow Effects | Durable for decorative use, but can fade under high heat |

| Color Anodizing (Dyeing) | Blue, Red, Yellow, Green, Purple, Pink, Champagne | 5-10 years (with proper sealing) |

Frequently Asked Questions

If you need an anodizing treatment service, please directly contact our team. Provide us with the details of your project, and we will offer you a tailor-made solution and quotation based on your specific requirements.

Yes, anodizing can be applied to parts of various sizes and shapes, including intricate geometries, ensuring uniform protection and finish.

Yes, anodizing is an eco-friendly process because it uses minimal chemicals, is water-based, and produces less waste compared to other surface treatments.

Yes, KingStar Mold offers tailored anodizing services to meet your specific design and functional requirements, including unique colors and finishes.

The lifespan of an anodized finish depends heavily on the type of anodizing (decorative vs. hard) and the environment in which the part is used. While decorative finishes prioritize aesthetics, hard anodizing prioritizes structural integrity.

Decorative anodizing: In an indoor environment with very little ultraviolet radiation, a clear anodized coating can remain intact for over 10 years without significant fading. However, in outdoor marine or coastal environments, saltwater accelerates corrosion and fading, reducing the actual lifespan to 5 to 7 years. The main problem is the cracking of the sealing layer, allowing moisture to seep in and causing “color bleeding” (color seepage).

Hard anodizing: Specifically designed to achieve extremely high durability, rather than merely for aesthetics. Due to its thickness (typically greater than 25 micrometers) and hardness (Vickers hardness of 400 and above), it does not “wear off” like paint. Its service life is the same as that of the underlying aluminum substrate. Studies have shown that a properly sealed hard anodized layer on aerospace alloys can maintain its anti-corrosion performance for up to 50 years under controlled conditions. In practical industrial applications, it is regarded as a permanent coating.

Anodizing is primarily used on aluminum and its alloys, though titanium, magnesium, and some other metals can also undergo specialized anodizing treatments.

Anodizing can be regarded as a highly controllable and accelerated corrosion process – but this process is beneficial to us, not detrimental to the metal. We use aluminium (mainly aluminium) as the anode (+) and place it in an acidic electrolyte. When an electric current is applied, its surface will directly transform into an extremely hard crystalline structure composed of aluminium oxide. The key point is: we do not coat it with some substance or electroplate it; instead, we directly change the outermost structure of the metal.