What Is Aluminum Extrusion?

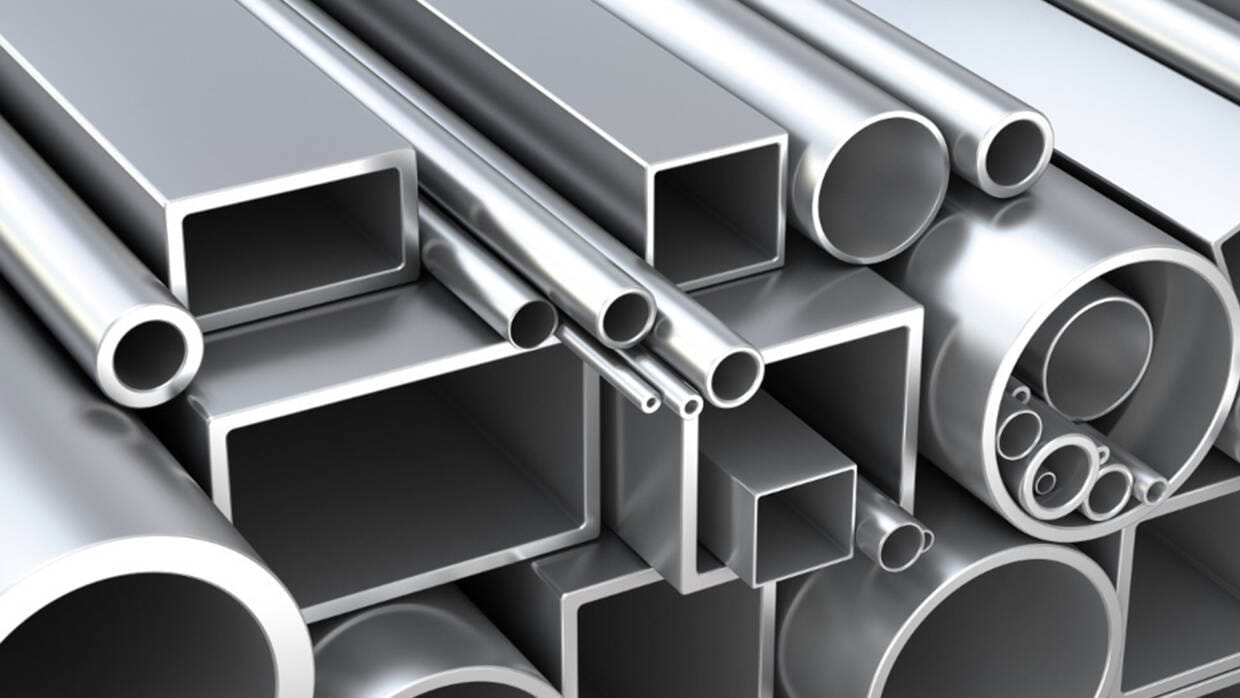

Aluminum extrusion is a manufacturing process where aluminum alloy is forced through a shaped die to create long profiles with a constant cross-section. This process allows for the production of complex, lightweight, and strong profiles with a variety of shapes, making it highly versatile for many applications. The extruded aluminum can be cut into specific lengths and can be used for a wide range of industries, including construction, automotive, and electronics.

The process begins with heating an aluminum billet to a malleable state and then pushing it through a die using high pressure. The result is a continuous aluminum shape that can be easily cut and finished to meet the specific needs of the customer. Aluminum extrusion offers several advantages, including excellent strength-to-weight ratio, corrosion resistance, and the ability to produce precise, custom shapes with minimal waste.

Key Benefits of Choosing KingStar Mold

High Precision and Expertise

Fast Turnaround and Competitive Pricing

Comprehensive One-Stop Service

Standard Extrusion

KingStar Mold offers a wide range of pre-engineered aluminum shapes designed for versatile applications across industries. Available in various sizes, these profiles are tailored to meet specific requirements for strength, durability, and ease of use. Whether for structural, automotive, or construction projects, our profiles provide reliable, cost-effective solutions with precise dimensions for a wide array of uses.

Standard Extrusion Profiles

Standard Extrusion Sizes

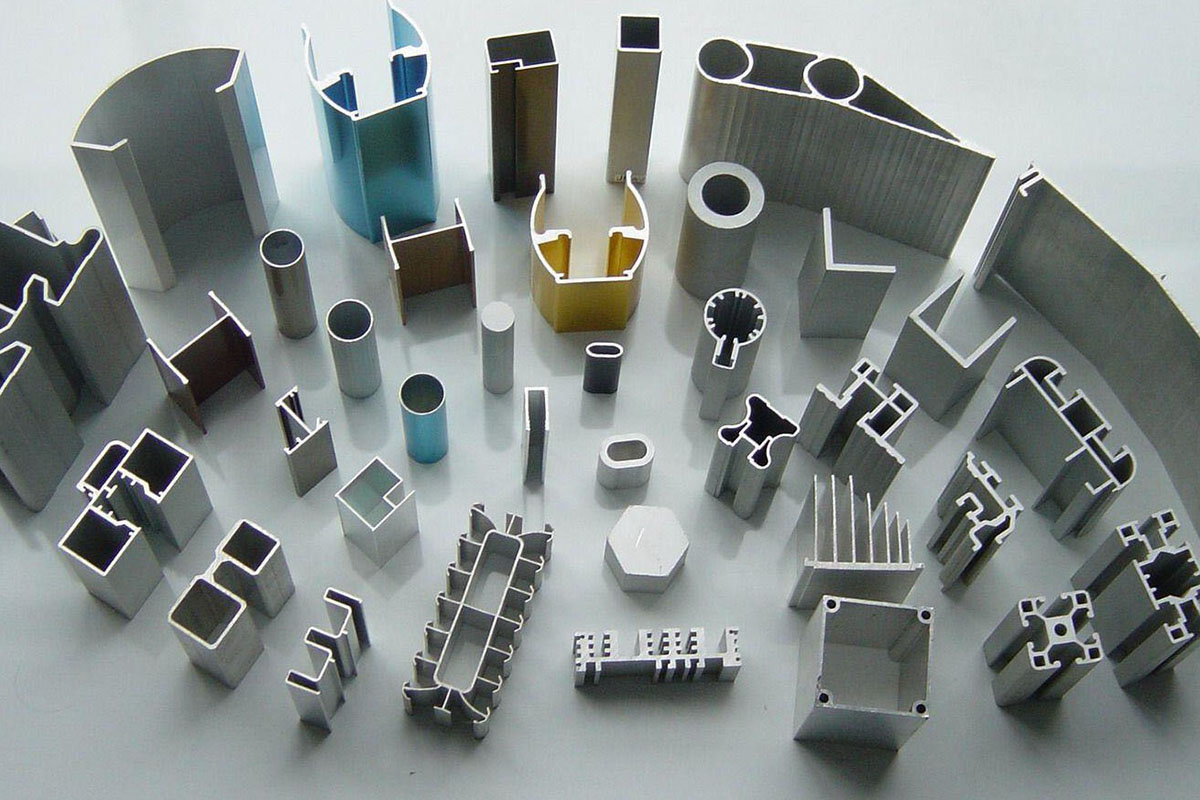

Custom Extrusion

KingStar Mold offers a wide range of pre-engineered aluminum shapes designed for versatile applications across industries. Available in various sizes, these profiles are tailored to meet specific requirements for strength, durability, and ease of use. Whether for structural, automotive, or construction projects, our profiles provide reliable, cost-effective solutions with precise dimensions for a wide array of uses.

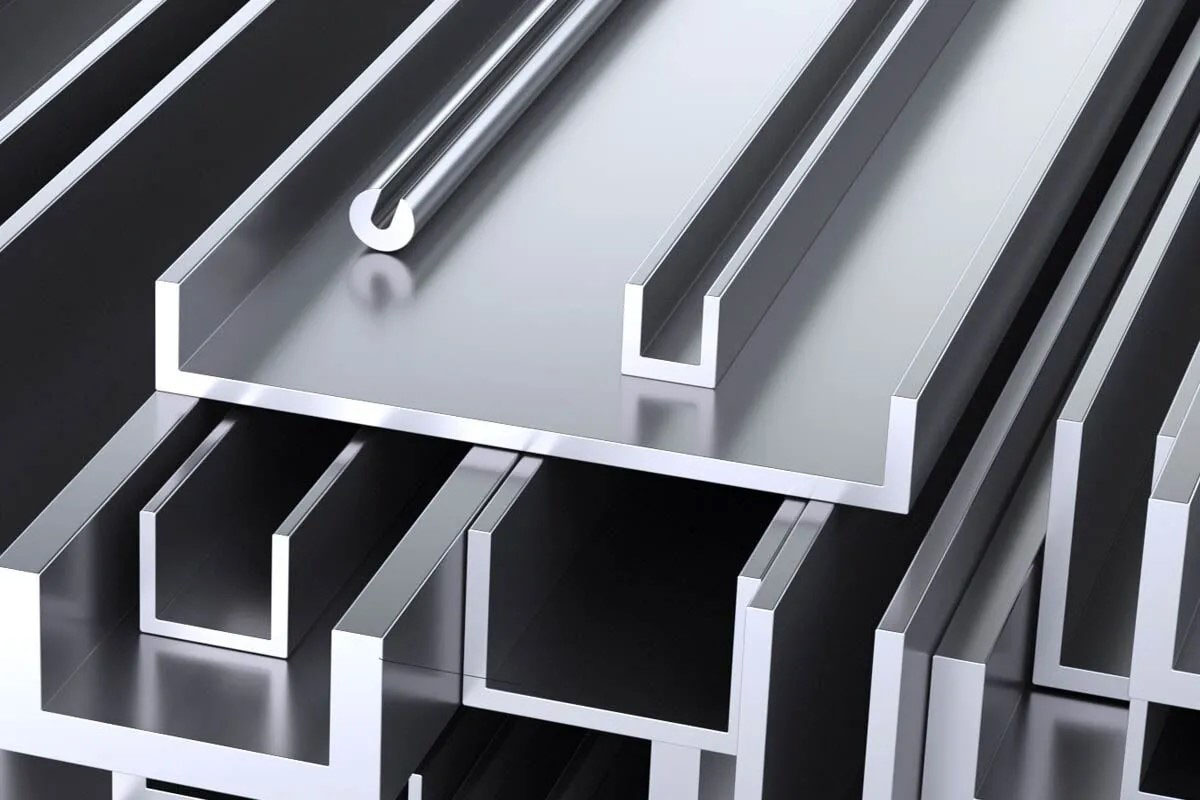

Aluminum Channels

Aluminum channels are versatile, U-shaped profiles used in construction and manufacturing for structural support, framing, and guiding purposes. They offer excellent corrosion resistance and can be easily customized for different applications.

Extruded Aluminum

Extruded aluminum is created by forcing heated aluminum through a die to form continuous shapes, making it ideal for producing complex profiles with precise dimensions. It is lightweight, strong, and resistant to rust, making it widely used in industries like construction, transportation, and electronics.

Aluminum Trims

Aluminum trims are decorative or protective finishing elements used to frame or edge various structures, often applied in windows, doors, and furniture. They are lightweight, durable, and resistant to corrosion, providing both aesthetic appeal and long-lasting protection.

Materials

Aluminum Alloys for Extrusion

Aluminum alloys for extrusion are specially formulated to optimize strength, flexibility, and workability during the extrusion process, making them ideal for creating complex shapes and profiles. These alloys offer excellent corrosion resistance, durability, and are often used in a wide range of industries, including construction, automotive, and aerospace.

Alloy 6061 is a versatile, heat-treatable aluminum alloy known for its excellent mechanical properties and good corrosion resistance. It is commonly used in industries such as aerospace, marine, and automotive for applications requiring high strength and weldability.

Alloy 6063 is a medium-strength, heat-treatable aluminum alloy with excellent finishability and corrosion resistance, often used in architectural and structural applications. It is popular for creating smooth, aesthetically appealing profiles in window frames, doors, and decorative components.

Alloy 7075 is one of the strongest aluminum alloys, offering high strength and excellent resistance to fatigue and stress corrosion, making it ideal for aerospace and military applications. Though it is less formable than other alloys, its high performance in extreme conditions makes it a preferred choice for critical structural components.

Alloy 1100 is a commercially pure aluminum alloy with excellent corrosion resistance, high ductility, and good workability, making it ideal for applications where high formability is required. It is commonly used in food processing, chemical equipment, and decorative applications due to its ease of fabrication.

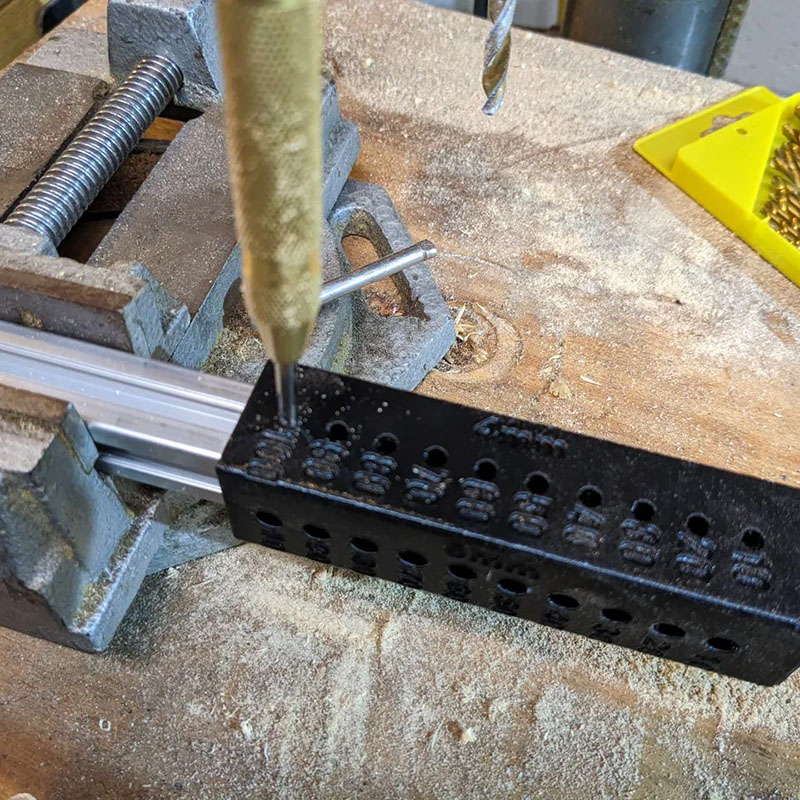

Post Machining Options For Aluminum Profiles

KingStar Mold provides a complete suite of surface treatment services for die-cast parts, aimed at improving their appearance, functionality, and longevity. Our offerings include polishing, anodizing, powder coating, and so on, all designed to enhance surface finish, corrosion resistance, and wear resistance. Through these treatments, we ensure your die-cast parts meet the highest quality standards, delivering the optimal finish for both visual appeal and performance needs.

Cutting

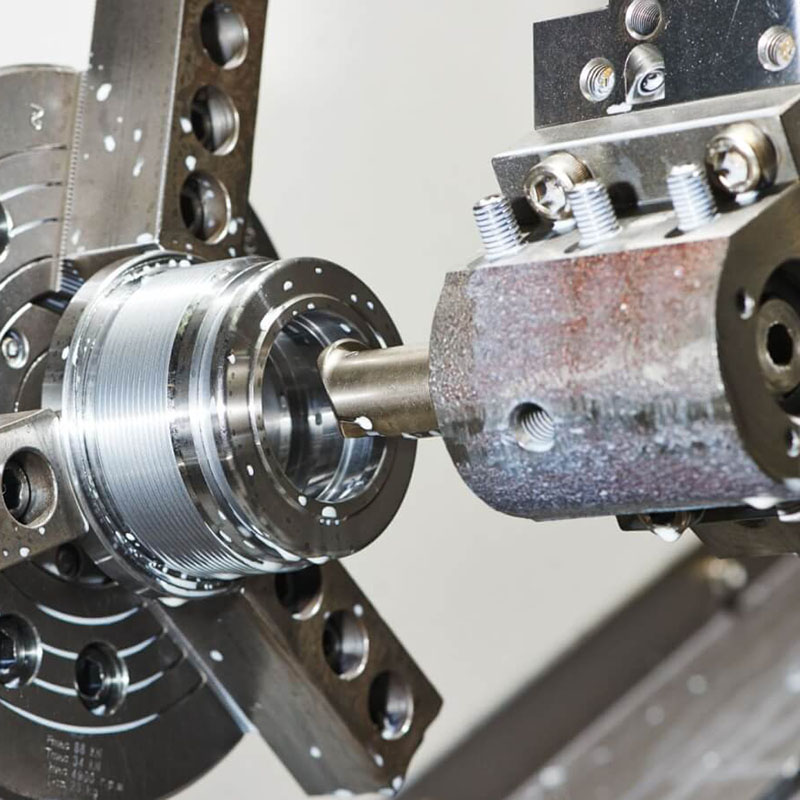

Grinding

Drilling

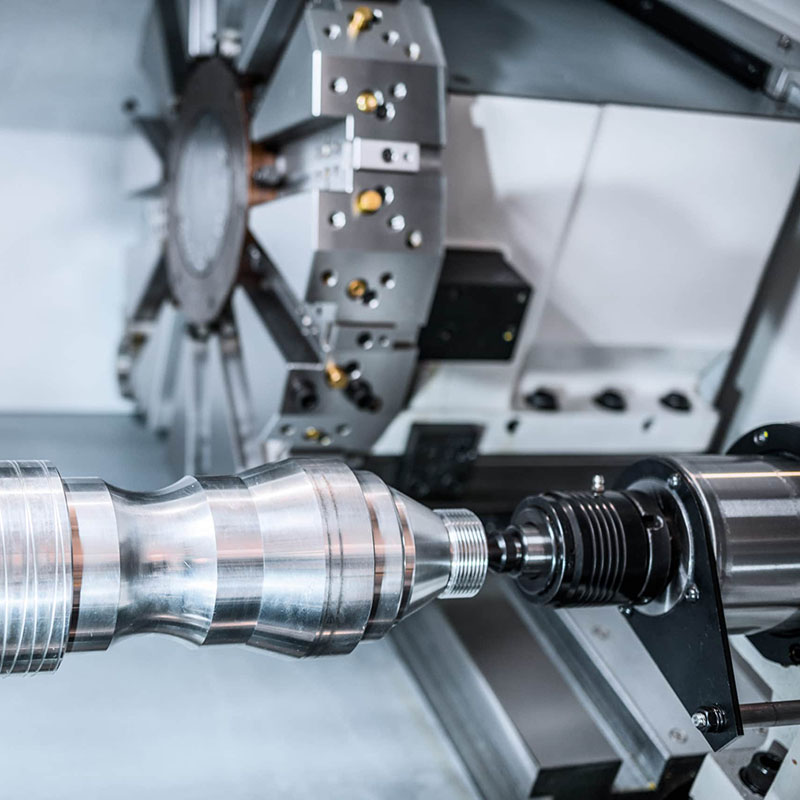

Turning

Deburring

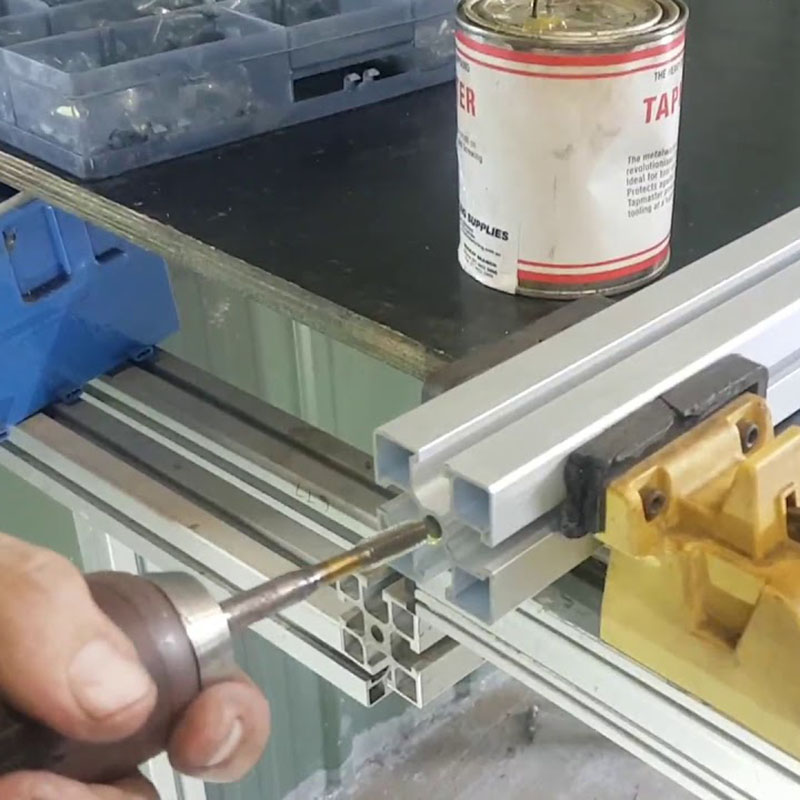

Tapping

Milling

Boring

20+

Types Available

400M+

Capacity Monthly

20+

Partnerships

10Y+

Experience

99%+

Satisfactory Rate

The right alloy for your project depends on factors such as required strength, corrosion resistance, and finish quality. It’s best to consult with experts at KingStar Mold, who can recommend the most suitable alloy based on your specific application.

At KingStar Mold, quality control is a priority. The company uses advanced techniques in die design, precise temperature management, and post-extrusion treatments like cooling and surface finishing to ensure each aluminum profile meets the highest standards of strength, durability, and appearance.

KingStar Mold offers extrusion services using a variety of aluminum alloys, including 6061, 6063, and 7075, each selected for its specific properties such as strength, corrosion resistance, and formability. The right alloy is chosen based on the requirements of the customer’s project.

Aluminum extrusion is a manufacturing process where aluminum is forced through a shaped die to create specific profiles. KingStar Mold specializes in providing high-quality aluminum extrusion solutions, offering customized profiles tailored to various industrial applications.

Die casting can be limited by high initial tooling costs, material choices (mostly non-ferrous metals), and size constraints for larger components.

KingStar Mold works closely with clients to create custom die casting designs, ensuring the parts meet specific functionality and design criteria.

KingStar Mold provides both hot chamber and cold chamber die casting, tailored to the specific material and size requirements of the part.

Die casting offers high precision, the ability to produce complex shapes, faster production cycles, and durable, strong components.