Aluminum 3D printing (typically referring to laser powder bed fusion/LPBF, or Selective Laser Melting/SLM) differs fundamentally from traditional manufacturing methods (such as CNC machining, casting, and forging) in terms of technical principles and application scenarios.

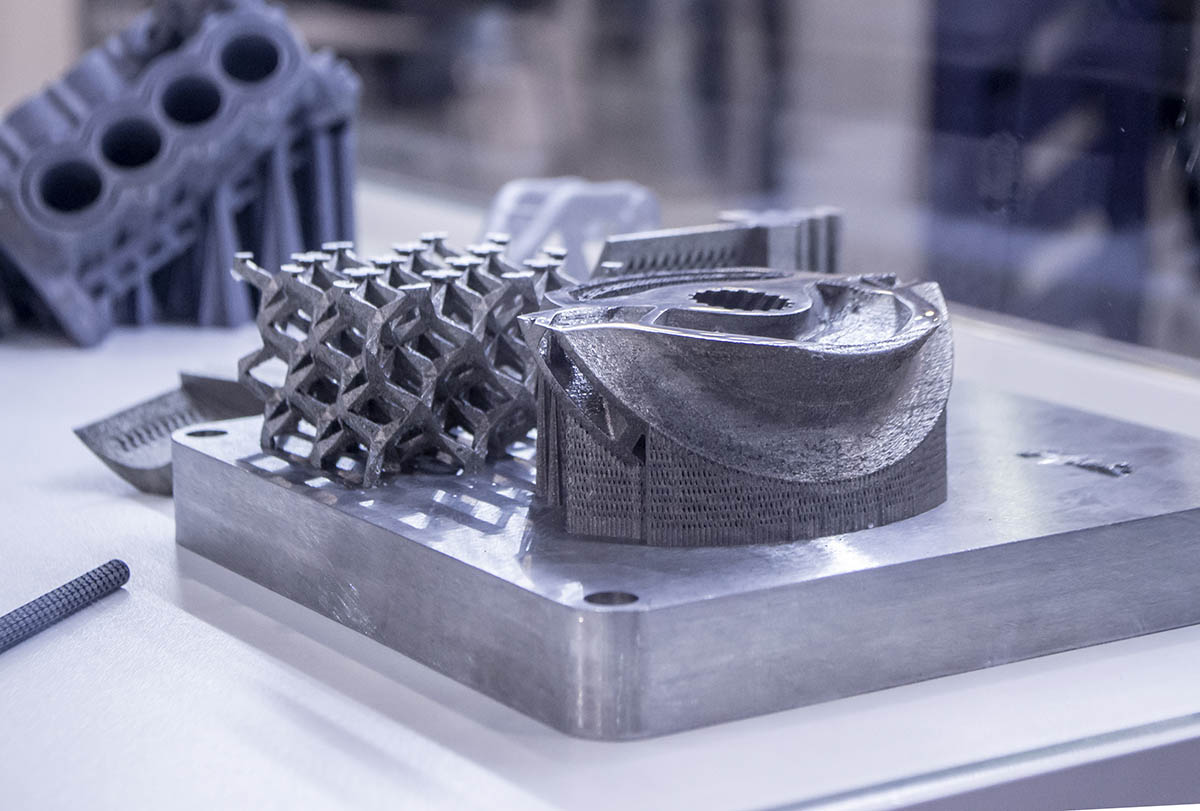

Firstly, from a technical perspective, 3D printing with aluminum falls under additive manufacturing (for example, SLM uses layer-by-layer melting of metal powder and cooling to form the final product). Most traditional manufacturing methods, on the other hand, belong to subtractive manufacturing, where excess materials are removed through methods such as cutting. Therefore, 3D printing is suitable for more complex structures, while traditional manufacturing is more cost-effective and thus suitable for the mass production of simple geometric shaped components. For the same reason, the design flexibility of aluminum 3D printing is extremely high. It can create internal channels, lattice structures, integrated components, and achieve topological optimization and lightweighting. However, traditional manufacturing is limited by the accessibility of tools and the parting lines of molds, making it difficult to achieve complex internal cavities and integrated structures.

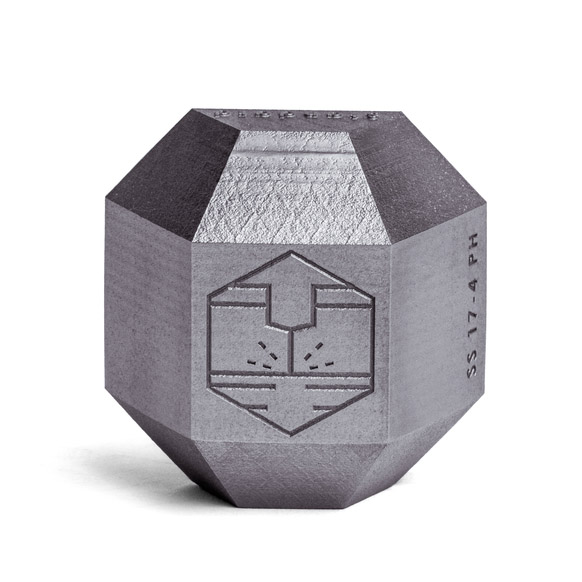

The types of aluminum used in these two manufacturing methods are also different. 3D printing uses common casting-grade aluminum alloys such as AlSi10Mg. The typical mechanical properties (in the printed state) are:

- Tensile strength: 330 – 460 MPa

- Yield strength: 215 – 365 MPa

- Elongation at break: 4 – 10%

- Density: ≥ 99%

After heat treatment (e.g. T6): The strength can be further increased to 400 – 460 MPa.

Traditional manufacturing usually employs deformation aluminum alloys such as 6061 and 7075. The typical mechanical properties (taking 6061-T6 as an example) are:

- Tensile strength: -310 MPa

- Yield strength: -276 MPa

- Elongation: -12%

The performance of casting parts is usually lower than that of forged parts or machined parts.

In certain circumstances, the strength of 3D-printed aluminum alloys (such as AlSi10Mg) has already matched or even exceeded that of some traditional cast aluminum alloys, but anisotropy needs to be taken into account. Traditional forged or rolled aluminum materials may have better toughness and fatigue performance.

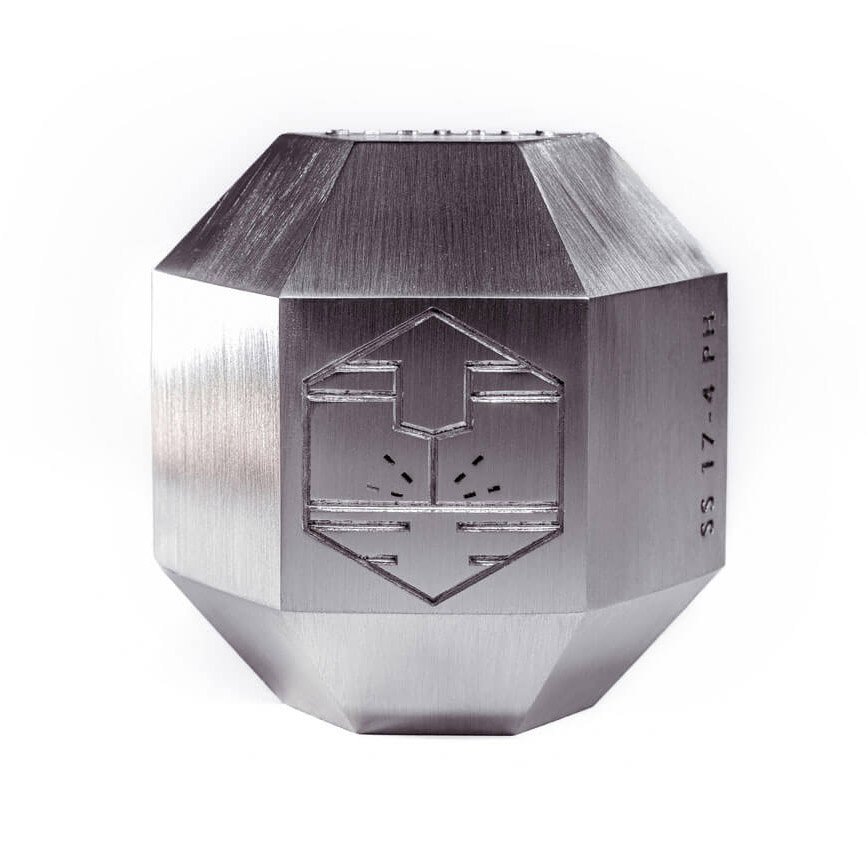

In terms of dimensional accuracy and surface roughness, CNC machining typically outperforms 3D printing: The typical accuracy of 3D printed components is ±0.1mm, and for some high-precision equipment, it can reach ±0.05mm. The surface roughness is mostly in the range of Ra 2-10 μm, as the unprocessed surface is prone to powder adhesion and layer lines; while the typical accuracy of CNC machined parts can reach 0.01mm or higher, with a surface roughness of Ra < 0.8 μm, achieving a mirror-like effect.

However, the material utilization rate of 3D printing is significantly higher than that of CNC, reaching over 95%. The powder can be basically recycled for reuse, while CNC processing generates a large amount of chips. The production cycle of 3D printing is also significantly faster than that of CNC. From a digital model to a prototype part, it only takes a few hours to a few days. There is no mold cost, so it is highly suitable for prototype verification, small batch production or customized manufacturing.