What Is Alodine? (aka Chem Film)

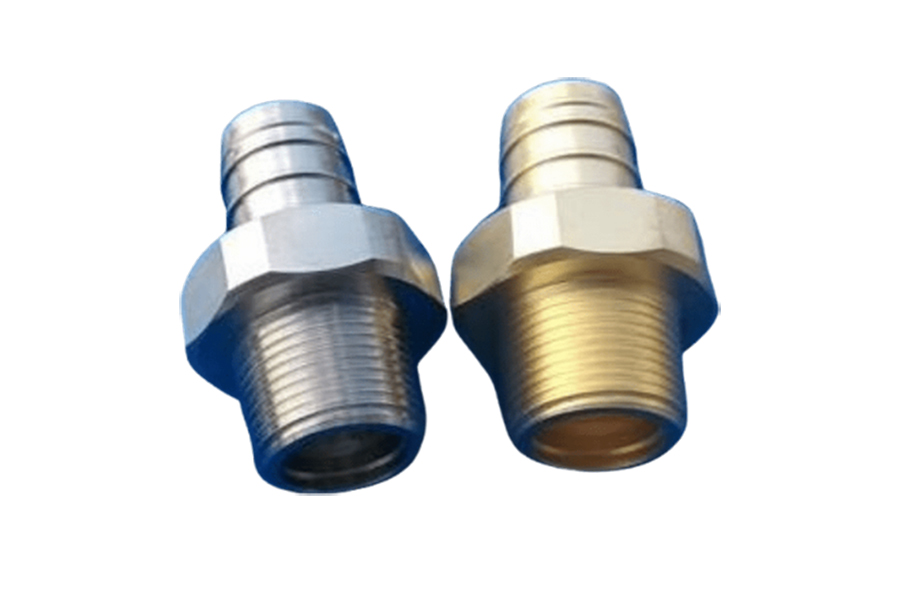

Alodine—commonly called Chem Film—is a specialized chromate conversion coating designed for aluminum and its alloys. Its primary role is to boost two critical metal properties: corrosion resistance and surface adhesion (key for paint or primer application).

Originally a trademark of Henkel for aluminum chromium oxide coating technology, the term “Alodine” has since become a generic industry reference—even though Henkel later rebranded the product as Bonderite®. A major advantage of Alodine coating is its thin, non-intrusive layer: it protects metal without altering its original strength or weight, making it ideal for high-stakes sectors like aerospace, military, and industrial manufacturing (where precision and durability matter most). Specifically, it works well for precision aluminum components that need to retain tight dimensions or parts requiring pre-treatment before painting, as its adhesion boost keeps coatings from chipping. But it’s not universal—Alodine only works on aluminum and its alloys (not steel, copper, or magnesium), can’t stand up to severe corrosion like saltwater, and isn’t durable enough for high-wear parts that rub against other components.

Specifications for Alodine Finish Service

| Parameter | Specification |

|---|---|

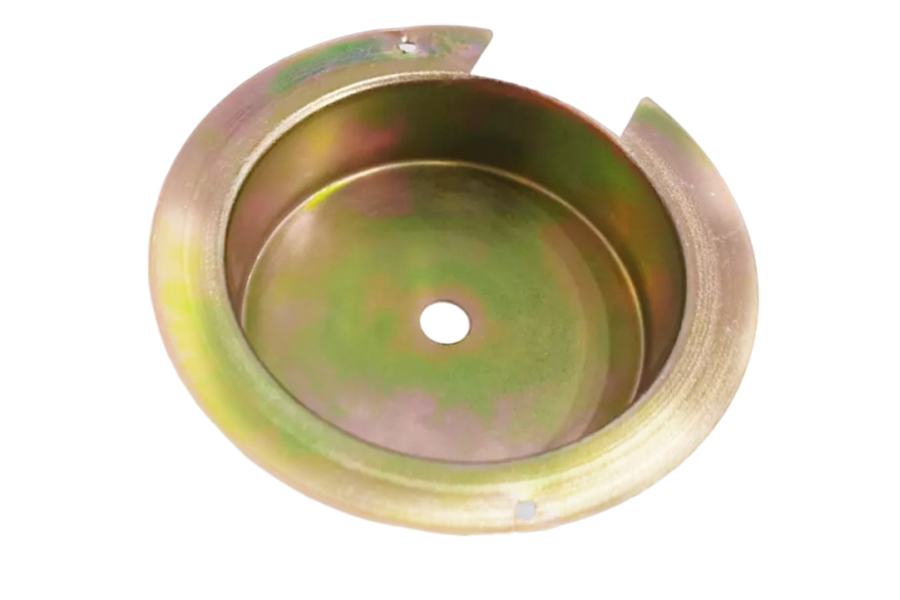

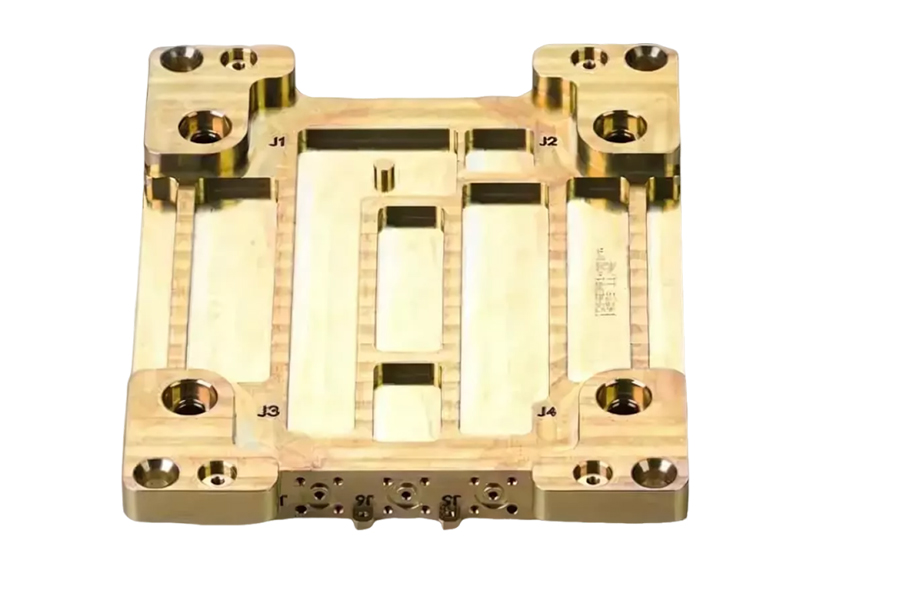

| Color | Golden, brown, transparent, or iridescent greenish-gold, depending on the Alodine type (e.g., Alodine 1000, 1001, 1200S, 5992) |

| Thickness | Typically 0.00001 to 0.00004 inches (0.25–1 μm) |

| Immersion Time | 1 to 5 minutes, depending on the size of the part and desired coating thickness |

| pH Value | 1.5 to 2.0 |

| Temperature | 70 to 100°F (21 to 38°C) |

| Standard Types | - MIL-DTL-5541 Type 1A: Minimum thickness 0.0001 inches (0.1 mil) - MIL-DTL-5541 Type 3: Maximum thickness 0.00001 inches (0.01 mil) |

| Special Types | - Alodine 1200S: Colorless or golden - Alodine 871: Hex-free, trivalent chromium-based - Alodine 5200, 5700, 5992: Other industrial applications |

| Minimum Part Size (mm) | 2×2×2 |

| Maximum Part Size (mm) | 3000×2200×1100 |

MIL-DTL-5541 Standard and Process We Apply for Alodine Finish

At our facility, we don’t just follow the MIL-DTL-5541 standard—we tailor it to fit the unique needs of your industry and parts, ensuring compliance and performance that aligns with real-world use. Below is how we apply the standard, plus our specialized insights to match the right coating and process to your project.

The standard’s Type I (hexavalent chromium) and Type II (hexavalent-free) classes each have strengths—but we help you pick the one that balances protection, conductivity, and compliance for your specific application:

We’ve refined the standard processes to address common pain points (e.g., uneven coating on complex parts, residue that harms adhesion) and match the material/use case of your components.

What’s the Difference between Alodine Coating & Anodizing?

| Comparison Dimension | Alodine Coating (Chem Film) | Anodizing |

|---|---|---|

| Core Type & Formation | Chemical conversion film: Forms via a chemical reaction between aluminum and chromate solution (no electricity required). | Electrochemical oxide layer: Grows via electrolysis (aluminum acts as anode in acid bath), thickening the metal’s natural oxide layer. |

| Typical Thickness | Ultra-thin: 0.25–1 μm (0.00001–0.00004 inches); minimal impact on part dimensions. | Thicker: 5–25 μm (0.0002–0.001 inches) for standard use; up to 100 μm for high-wear applications. Adds measurable thickness to parts. |

| Corrosion Resistance | Moderate: Protects against mild moisture/pollutants (e.g., indoor use). Unpainted Alodine fails in harsh environments (saltwater); works best as a pre-coat for paint. | Superior: Dense oxide layer resists saltwater, UV, and chemicals. Ideal for outdoor/harsh conditions (e.g., marine parts, outdoor furniture) without additional topcoats. |

| Abrasion & Wear Resistance | Poor: Thin film offers little protection against friction or impacts; easily worn off. Not suitable for high-wear parts. | Excellent: Hard oxide layer (up to 60+ Rockwell hardness) withstands scratches, rubbing, and mechanical stress. Used for parts like tool handles or bicycle frames. |

| Electrical Conductivity | High: Thin film preserves aluminum’s conductivity (critical for electrical components). Class 3 Alodine is optimized for minimal conductivity interference. | Low/Insulating: Thick oxide layer is non-conductive; disrupts electrical bonding. Not recommended for grounding parts or electronic enclosures. |

| Paint Adhesion | Excellent: Rough, porous surface creates a strong bond with paint/primer. Class 1A Alodine is industry-standard for aerospace/automotive pre-painting. | Poor (without treatment): Smooth oxide layer repels paint. Requires etching or priming to improve adhesion—adds extra process steps. |

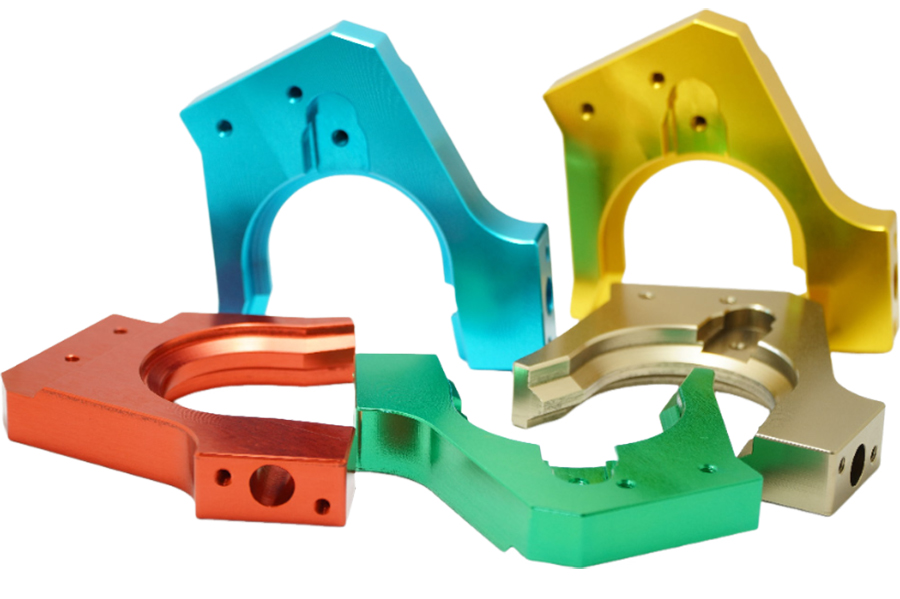

| Color Options | Limited: Translucent, golden, brown, or iridescent greenish-gold (depends on Alodine type, e.g., 1200S is colorless). No vibrant or custom colors. | Wide: Can be dyed to nearly any color (red, blue, black, etc.) or left natural (clear/silver). Electrolytic coloring creates durable, fade-resistant hues. |

| Process Complexity & Cost | Simple & Low-Cost: No electricity needed; uses immersion/spraying. Fast (1–5 minutes per part). Lower equipment/maintenance costs. | Complex & Higher-Cost: Requires electrolytic tanks, power supplies, and precise acid bath control. Longer process (30–60 minutes per part). Higher upfront/operational costs. |

| Environmental Impact | Riskier (Type I): Contains hexavalent chromium (carcinogenic); requires hazardous waste disposal. Type II (hex-free) is safer but still needs chemical management. | Moderate: Uses sulfuric/nitric acids; generates acidic wastewater (must be treated). No heavy metals (e.g., chromium) in standard processes. |

| Ideal Applications | - Aerospace/defense: Pre-paint base for fuselage parts, electrical bonding components. - Electronics: Enclosures, heat sinks, grounding parts. - Automotive: Engine brackets (pre-painted). | - Decorative: Outdoor furniture, consumer goods (e.g., smartphone cases). - High-wear: Tooling, marine hardware, bicycle components. - Corrosion-prone: Coastal infrastructure, outdoor lighting. |

| Compliance Standards | MIL-DTL-5541 (military/aerospace), AMS 2471 (aerospace). | MIL-A-8625 (military), ISO 7599 (aluminum anodizing), ASTM B580. |

Frequently Asked Questions

Yes. One of Alodine’s key benefits is improving paint adhesion, making it an excellent base layer for subsequent painting or powder coating. But compared to Class 3, Class 1A provides better adhesion for the paint.

No, Alodine coating isn’t universal for all aluminum alloys—it works best on most common aluminum grades but may require extra preparation (or isn’t ideal) for certain types, depending on their alloy composition.

Most heat-treatable aluminum alloys (e.g., 6061, 7075, 2024) are perfect for Alodine: their composition (with moderate amounts of magnesium, silicon, or copper) reacts consistently with chromate solutions, forming a uniform, durable coating—this is why they’re widely used in aerospace and automotive parts treated with Alodine.

However, high-silicon aluminum alloys (e.g., 3003, 3105, or die-cast aluminum like A380) need extra steps: the silicon in these alloys can create a “barrier” that stops the chromate reaction, leading to patchy or thin coatings. For these, we typically add a pre-etch step with a specialized acid to remove excess surface silicon before applying Alodine, ensuring the coating adheres evenly.

Pure aluminum (1000 series, e.g., 1100) also works with Alodine, but the coating may be slightly lighter in color and offer marginally less corrosion resistance compared to heat-treatable alloys—this makes it suitable for low-stress parts (e.g., decorative trim) but less ideal for harsh environments.

If you’re unsure about your alloy, we recommend sharing the aluminum grade (e.g., 6061-T6) with your coating provider—they can test or adjust the process to match your material.