Additive Post-Processing Services

A model printed entirely using our in-house additive manufacturing technologies, and carefully finished by hand by our KingStar post-processing team

What is Additive Post-Processing?

KingStar Mold’s Additive Manufacturing: More Than Post-Processing

At KingStar Mold, our one-stop additive manufacturing service not only brings convenience, but also represents a strategically significant advantage, aiming to eliminate the obstacles caused by decentralized workflow. Unlike collaborating with various design companies, 3D printers, processing parties, and quality inspection laboratories, every stage of your project is under our control: from the moment your design files are sent to our engineering team, until the final round of quality inspection before shipment. This integration means no information transmission errors, no unclear specifications, and no delays caused by waiting for external suppliers to coordinate. When your parts transition from the design file analysis stage to the printing stage and then to the post-processing stage, the same team that optimized the design will be responsible for adjusting the surface treatment effect to ensure that every decision serves your ultimate goal.

Our in-house ecosystem creates invisible but critical synergies. During design reviews, our engineers don’t just focus on printability; they map out how post-processing will enhance (or challenge) your part’s performance, adjusting geometries early to avoid costly reworks. When 3D printing begins, real-time data flows directly to our post-processing team – so vapor smoothing times are calibrated to your print’s exact layer height, and machining tolerances account for material shrinkage. Even quality checks are integrated: our inspectors use 3D scans of the as-printed part to validate that post-processing hits your specs, with instant feedback loops to refine steps if needed.

A recent robotics client saw their timeline cut by 25% compared to their previous multi-vendor approach. We caught a design flaw during DFM that would’ve derailed post-processing, fixed it in days, and delivered finished parts that dropped seamlessly into their assembly. For you, it means more control, less risk, and a final part that meets your vision – from first sketch to final shipment.

Our Core AM Post-Processing Services by Functional Scenarios

Surface Optimization Services

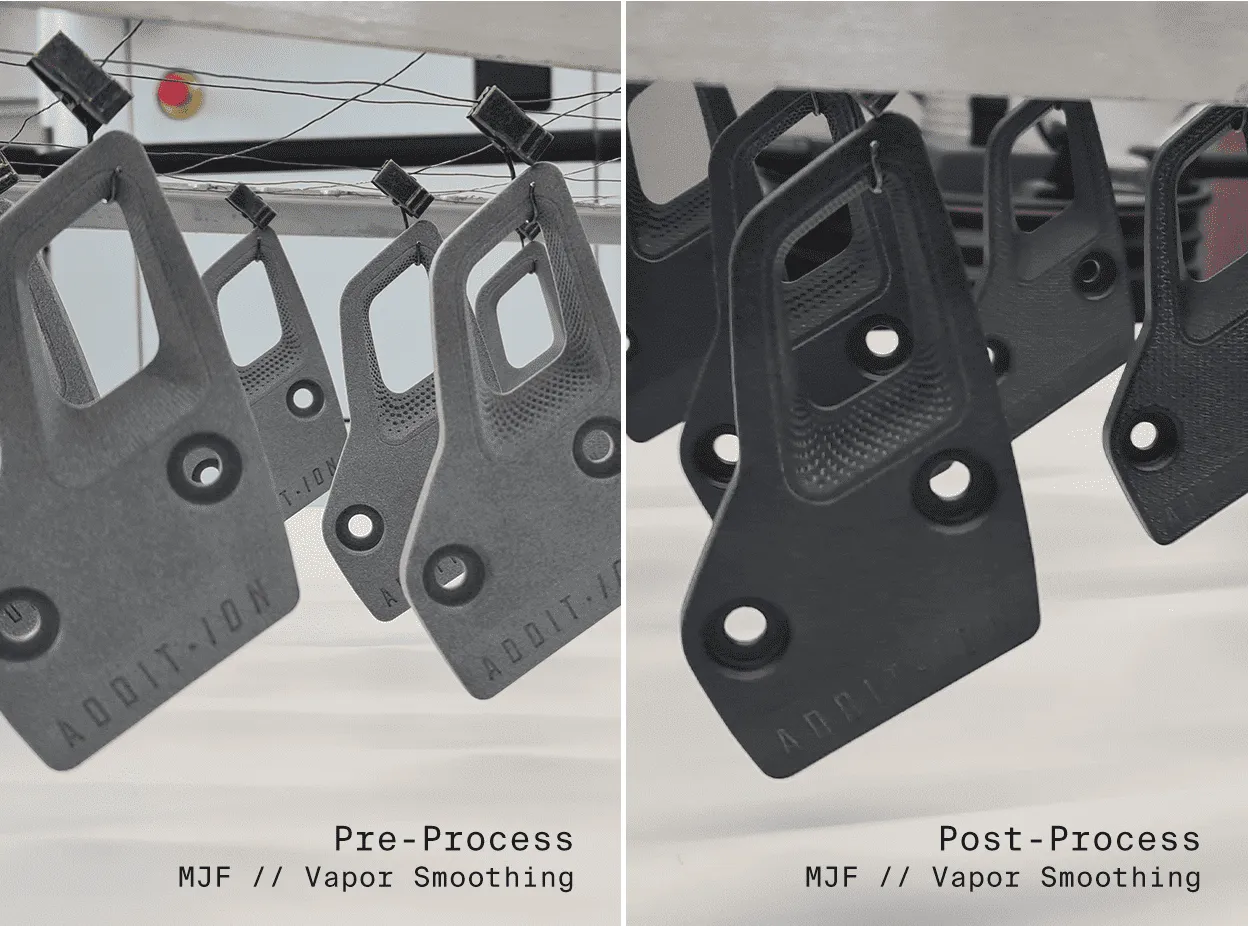

Vapor Smoothing

Chemical vapor melts part surfaces to seal pores and smooth thermoplastics (PA12, ABS), boosting paint adhesion and preventing fluid leakage.

Performance Enhancement Services

Hot Isostatic Pressing (HIP)

Applies uniform heat/pressure to metal parts, eliminating voids to boost density, tensile strength, and fatigue resistance (critical for aerospace).

Resin Impregnation

Injects low-viscosity resin into porous SLS/MJF parts to fill gaps, strengthening structure and improving sealability for fluid-handling components.

Aesthetic & Customization Services

Custom Painting

Single or multi-layer (primer + topcoat) options with Sikkens color-matching (Pantone/brand hues). Suits branding or EMI shielding needs.

Dye Infusion

Water-based dyes penetrate nylon/resin parts, delivering uniform color on complex geometries without obscuring details and is great for decorative/color-coded parts.

Metal Plating

Chrome (hardness/finish), nickel (corrosion resistance), gold (conductivity) plating for metal parts, serving functional and aesthetic needs.

Assembly & Precision Adjustment Services

Insert Installation

Press-fitted/heat-staked threaded inserts (metal/plastic) for PolyJet/SLA parts, creating strong, reusable connection points.

How to Choose the Right Post-Processing Solution?

Post-Processing Services Using Additive Technology

Explore the full range of post-processing and finishing services available for each of the seven additive manufacturing technologies we support.

| Post-Processing Service | FDM | SLA | SLS | DMLS | MJP | MJF |

|---|---|---|---|---|---|---|

| Sanding | √ | √ | √ | √ | √ | √ |

| Extrude Hone (AFM) | √ | √ | √ | √ | ||

| Media Blasting (Glass bead) | √ | √ | √ | √ | √ | √ |

| Media Blasting (Al Oxide 100g) | √ | √ | √ | √ | ||

| Media Blasting (Steel shot) | √ | |||||

| Insert Installation (Press-fit only for PolyJet and SLA) | √ | √ | ||||

| Electrochemical Polish | √ | |||||

| Stainless Passivation | √ | |||||

| Sand & Paint (Non-Cosmetic) | √ | √ | √ | √ | √ | √ |

| Sand & Paint (Cosmetic Finish) | √ | √ | √ | √ | √ | √ |

| Custom Paint per Spec | √ | √ | √ | √ | √ | √ |

| Specialty Coatings* | √ | √ | √ | √ | √ | √ |

| Dye Infusion | √ | √ | √ | |||

| Metal Plating | √ | |||||

| Decal Application | √ | √ | √ | √ | √ | √ |

| Pad Printing | √ | √ | √ | √ | √ | √ |

| Screen Printing | √ | √ | √ | √ | √ | √ |

| Tumbling | √ | √ | √ | √ | ||

| Secondary Machining | √ | √ | √ | √ | √ | √ |

| Mechanical Assembly | √ | √ | √ | √ | √ | √ |

| EMI Shield Paint | √ | √ | √ | √ | √ | √ |

| Heat Treatment | √ | |||||

| Polishing + Clearcoat Option | √ | √ | √ | √ | √ | √ |

| Hot Isostatic Pressing (HIP) | √ | |||||

| Vapor Smoothing | √ | √ | √ |

*KingStar Mold offers a broad spectrum of customer-specific finishing options, including epoxy coatings and specialized paints. Reach out to your sales representative to discuss your project’s unique requirements.

Benefits of KingStar Mold’s Post-Processing Services

Why choose KingStar Mold’s expert post-processing services to elevate your 3D-printed parts? Here are key advantages:

10+ Years of Specialized Expertise

We have over 10 years of experience in additive post-processing, with sufficient project experience ranging from agricultural machinery to aerospace fields, including large agricultural machinery components (FDM printing) to precision DMLS metal components.

End-to-End In-House Workflow

From the design review to DfM optimization, to 3D printing, post-processing, and quality inspection, we can handle every process step for you, avoiding the obstacles and mismatch of requirements that often occur when communicating with different service providers.

Engineering Involvement from DAY ONE

We can incorporate post-processing factors into our design stage through DfM optimization, thereby preventing the post-processed parts from failing to meet the initial tolerances and required rework afterwards.

Custom Solutions for Unique Needs

We deliver specialized coatings (e.g., chemical-resistant epoxies) and extreme environment adaptations (high-heat, corrosive settings), tailoring processes to your project’s demands.

Frequently Asked Questions

At KingStar Mold, we combine in-house post-processing capabilities with a highly experienced team to deliver consistent, high-quality results, faster and more reliably than outsourcing to multiple vendors. Whether you need sanding, vapor smoothing, painting, or precision machining, we handle every step under one roof to streamline production and eliminate delays.

On top of that, we offer one-stop manufacturing solution, which includes all manufacturing processes from initial design review to prototype printing to full-scale production (and with quality control spreading the whole workflow). We simplify your supply chain by offering seamless support. That means fewer touchpoints, tighter quality control, and faster delivery which are all tailored to your specific performance and cosmetic requirements.

Yes, KingStar Mold can match specific colors and finishes, whether you’re looking for custom paints, specialty coatings, or consistent dye shades. Just share your specifications and we’ll tailor a finishing solution for your project.