Consumer Electronics

Appliances

Medical Devices

EV & Automotive

ABS plastic fabrication is commonly used in both everyday products and industrial applications, with the examples above representing just a fraction of its versatility. At KingStar Mold, we have extensive expertise in ABS injection molding, including working with modified ABS materials such as PC+ABS, ABS+PA, ABS/PBT, and Flame-Retardant ABS.

ABS Injection Molding Process Step-By-Step

ABS injection molding is a systematic and precise manufacturing process. To ensure the quality of the final product, each step requires strict control of process parameters. The following is a detailed step-by-step explanation of the ABS injection molding process based on industry practice and specific data.

Mainstream ABS Materials Property Comparison

| Grade / Brand | Manufacturer | Type / Key Features | Tensile Strength (MPa) | Flexural Modulus (GPa) | Notched Impact (kJ/m²) | Heat Distortion Temp (°C, 1.8 MPa) | Melt Flow Rate (g/10 min) | Density (g/cm³) | Shrinkage (%) | Rockwell Hardness (R) |

|---|---|---|---|---|---|---|---|---|---|---|

| PA-757 | CHIMEI | General injection grade, high rigidity & gloss | 47 | 2.2 | 19 | ~83 | ~19 | 1.19 | 0.3–0.6 | 100 |

| PA-765 / PA-765A | CHIMEI | High flow / flame retardant ABS | ~38 | 1.8 | ~23 | ~76–84 | ~46 | 1.17–1.19 | 0.3–0.6 | 100–101 |

| HI-121H | LG Chem | General injection grade, high gloss, heat stable | ~46 | ~2.3 | ~22 | ~79 | 22 | — | — | — |

| GPM5500 | SABIC (GE) | Multipurpose injection grade, high flow | — | 2.30 (approx) | ~10 | ~76 | — | — | — | — |

| Cycolac MG47 | SABIC | Balanced engineering performance | ~44 | ~2.3 | ~23 | ~80–94 | — | 1.04 | 0.5–0.8 | 112 |

| TERLURAN® HI-10 | INEOS Styrolution | High impact ABS with very high toughness | 38 | ~1.9 | 36 | ~97** | ~5.5 | — | — | — |

| TERLURAN® 967K | BASF/INEOS | General injection grade | 50.0 | — | — | — | — | 1.03–1.04 | 0.4–0.7 | — |

| Lustran® 348 | INEOS Styrolution | General ABS | 48.3 | 2.69 | — | — | — | 1.06 | 0.4–0.6 | 112 |

| RTP 605 (30% GF) | RTP | Glass-fiber reinforced ABS | 96.5 | 8.27 | — | — | — | 1.27 | 0.1–0.2 | — |

Note: Some commercial-grade products, such as TERLURAN® 967K and TERBLEND® S 7960S, do not have publicly available complete performance charts; to obtain the complete numerical data, please wait for our technicians to confirm after placing your order.

ABS Plastic Solutions

Our ABS Plastic Parts Production Capabilities

KingStar Mold’s state-of-the-art facility houses a wide range of injection molding machines specifically designed for ABS plastic production. This setup enables us to deliver ABS molding services with high precision and adaptability, meeting diverse client needs with exceptional quality.

Our team’s deep expertise in ABS enables us to utilize the latest technologies to produce durable, high-quality components for a wide range of applications.

Key Benefits of Choosing KingStar Mold for ABS Molding

ABS injection molding offers a range of advantages, making it an ideal choice for many applications.

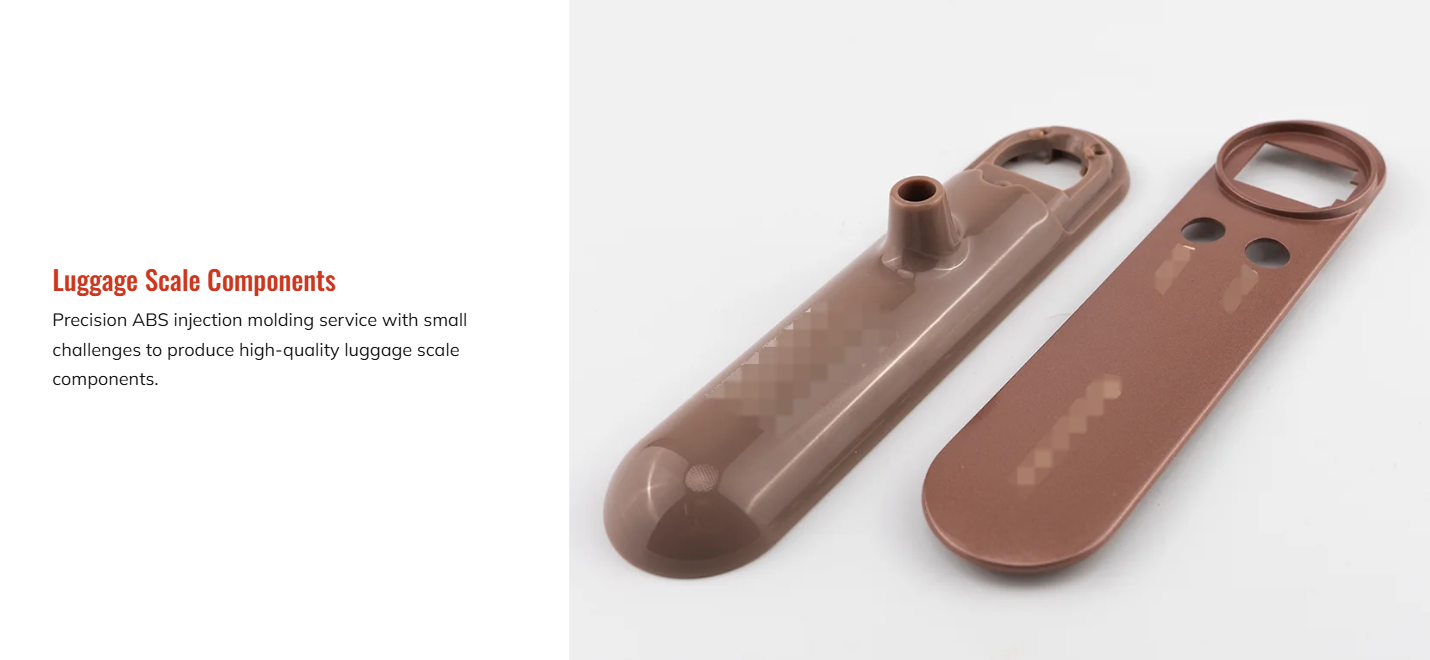

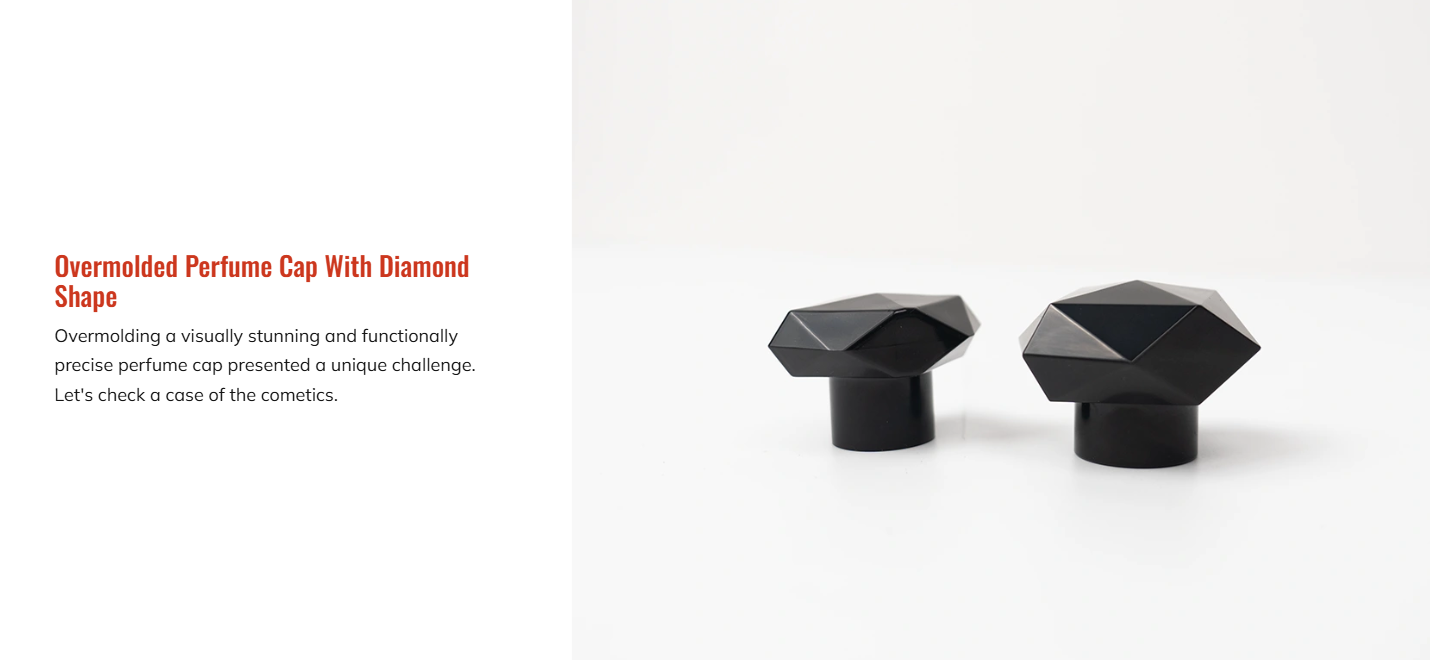

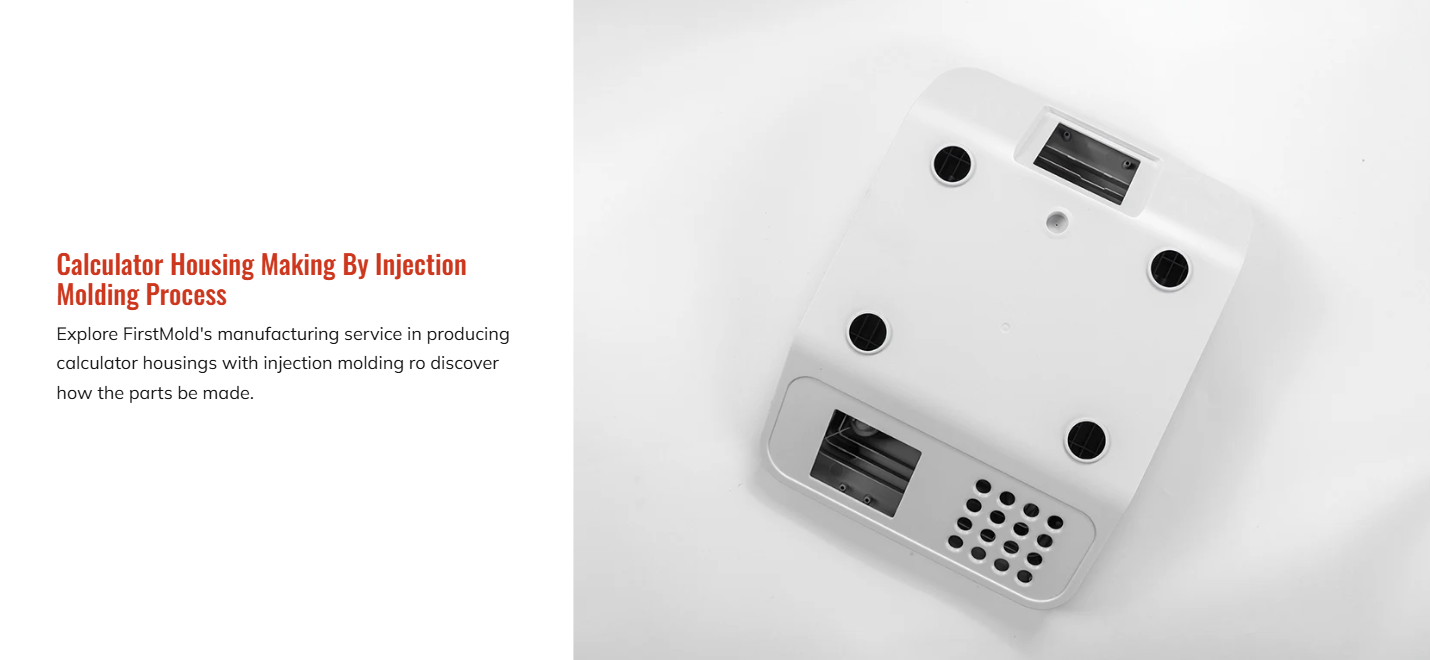

ABS Injection Molding Cases

Custom ABS molding requires careful drying and process control to prevent moisture-related defects, warping, and shrinkage, along with precise mold design to guarantee high-quality finishes and part integrity. This process demands the expertise of skilled engineers and advanced machinery to ensure optimal results.

Frequently Asked Questions

Yes, ABS is suitable for intricate and thin-walled designs. By adjusting injection pressure and ensuring a precise flow rate, we achieve optimal fill for complex designs. Our engineers carefully design the molds to prevent issues like short shots or incomplete fills in thin-walled or detailed areas.

Injection molding requires the design and manufacture of molds, and its cost and manufacturing time will increase as the complexity of the part increases. Therefore, the initial investment for injection molding is very high, and a certain minimum production volume is required to recover the cost of mold design and manufacturing. This break-even point also depends on the expected selling price of the final product. If the selling price is higher (for example, the part is used for special purposes), then small batch production can be carried out. However, for low-cost parts, a large-scale production of tens of thousands of pieces is required to achieve cost-effectiveness.

If there are special requirements, it is recommended to use aluminum molds or silicone molds instead of the traditional multi-chamber steel molds. Aluminum molds have good heat conductivity, short production cycle, and the cost is approximately 30%-50% of that of steel molds. However, their lifespan is relatively short (about 50,000 – 100,000 times), making them suitable for small and medium batch production of several thousand pieces. Silicone molds are suitable for lower production volumes (from dozens to hundreds of pieces), and are often used in combination with polyurethane (PU) casting, but their material performance and efficiency are lower than direct injection molding.

Individually, ABS does not inherently possess natural UV resistance. It may degrade under sunlight exposure over time. For applications requiring UV resistance, we recommend adding UV stabilizers to the raw ABS pellets before or during the molding process, or coating the surface of the components with a material that has UV resistance properties. This ensures that the components can maintain their appearance and structural integrity even when exposed to UV light for an extended period.

| Defect | Main Visual Characteristics | Root Causes | Solutions |

|---|---|---|---|

| 1. Sink Marks | Local depressions or dimples on the part surface, commonly appearing on the opposite side of ribs or thick wall sections. | Uneven cooling shrinkage of the material. The core of thick sections cools slowly, causing the surface to be pulled inward during shrinkage. Insufficient packing pressure or packing time fails to compensate for shrinkage. | Design: Optimize wall thickness with smooth transitions; avoid localized thick sections. Process: Increase packing pressure and extend packing time to ensure sufficient material compensation. Slightly reduce melt temperature and extend cooling time. |

| 2. Warpage / Deformation | Part bends or twists after cooling, deviating from the intended shape. | Large differences in cooling rates across the part lead to uneven shrinkage and internal stress. Uneven ejection or premature demolding. | Mold: Optimize cooling channel layout to ensure uniform mold temperature. Improve ejector system balance. Process: Reduce mold temperature variation and extend cooling time. Lower injection pressure and speed to reduce internal stress. Design: Optimize part geometry, add reinforcing ribs, and avoid large flat areas. |

| 3. Silver Streaks / Splay Marks | Silver or white streaks on the surface, typically aligned with the flow direction. | Moisture in the material vaporizes at high temperature; excessive melt temperature causes thermal degradation; poor mold venting traps air. | Material: Thoroughly pre-dry ABS resin (typically 80–85 °C for 2–4 hours). Process: Reduce melt temperature and screw speed to prevent overheating and degradation. Lower injection speed for smoother filling. Mold: Inspect and improve venting to allow trapped air to escape. |

| 4. Short Shot / Incomplete Filling | Melt fails to completely fill the cavity, resulting in incomplete parts. | Insufficient injection pressure or speed; melt or mold temperature too low; gate or runner size too small; poor venting. | Process: Increase injection pressure, injection speed, and melt temperature. Raise mold temperature to improve flowability. Mold: Check and enlarge gate or runner dimensions; ensure adequate venting. |

| 5. Burn Marks / Black Streaks | Black or dark brown marks on the surface or at the flow end of the part. | Air trapped in deep cavity areas is highly compressed and rapidly heated (“diesel effect”), causing material burning. Excessively high melt temperature. | Mold: Improve venting as a priority; add vents at flow ends or air-trap areas. Process: Reduce injection speed (especially in the final stage) to allow air to escape. Lower melt temperature. |

| 6. Flash | Thin excess plastic along parting lines, inserts, or ejector pin holes. | Insufficient clamping force; excessive injection pressure; mold wear or poor parting surface fit; melt temperature too high. | Machine / Mold: Check and increase clamping force. Repair mold to ensure tight parting surfaces and restore worn areas. Process: Reduce injection pressure, injection speed, and melt temperature as appropriate. |

| 7. Weld Lines / Knit Lines | Visible lines at locations where two or more melt fronts meet, usually with reduced strength. | Melt fronts split and rejoin in the cavity; the leading edges cool before meeting, resulting in poor fusion. | Process: Increase melt and mold temperatures to improve melt fusion. Increase injection speed to shorten cooling time before melt fronts meet. Mold: Adjust gate location to change weld line position. Add overflow wells or vents at potential weld line areas. |

| 8. Delamination / Peeling | Layer-like separation or peeling on the part surface. | Material contamination (mixing incompatible plastics); severe moisture absorption; melt temperature too low causing poor plasticization. | Material: Ensure material cleanliness and avoid mixing different resin types or grades. Strictly follow pre-drying procedures. Process: Increase melt temperature and back pressure to ensure proper plasticization and homogenization. |

The ABS injection molding defects need to be analyzed comprehensively by considering “materials – molds – processes – equipment”. Usually, one defect may be caused by a combination of multiple reasons. When conducting the investigation, the principle of starting from the simple to the complex and from the surface to the interior should be followed: first, confirm whether the materials are fully dried; second, check whether the process parameters are within the reasonable range; finally, review whether there are fundamental limitations in the mold design. Through this structured approach, the root cause of the problem can be effectively identified, and long-term corrective and preventive measures can be implemented, thereby achieving stable, efficient, and high-quality production.