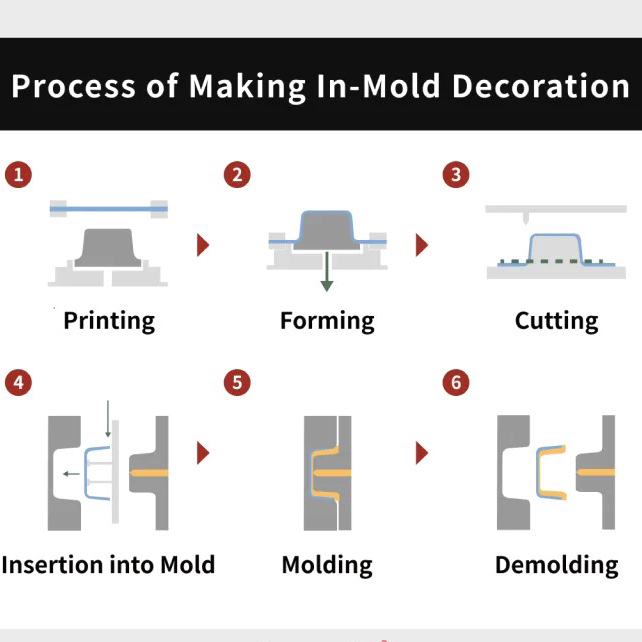

1. Process Background: New Exploration of IMD Technology

In recent years, in-mold decoration (IMD) has actually gained significant popularity in the field of product exterior processing—it enhances surface texture and enables diverse personalized designs, elevating the aesthetic appeal of products ranging from home appliance casings to consumer electronics accessories. However, a persistent issue remains unresolved: despite its remarkable utility, this technology has never been applied to thin-walled plastic components. As a leading plastic injection molding company, KingStar has rich experience in IMD technology and thin-wall injection molding, so we write this post to introduce the details of this new process.

2. Planning Phase: Clarify Goals and Address Challenges

2.1 Core Direction: Shorten Cycle and Reduce Wall Thickness

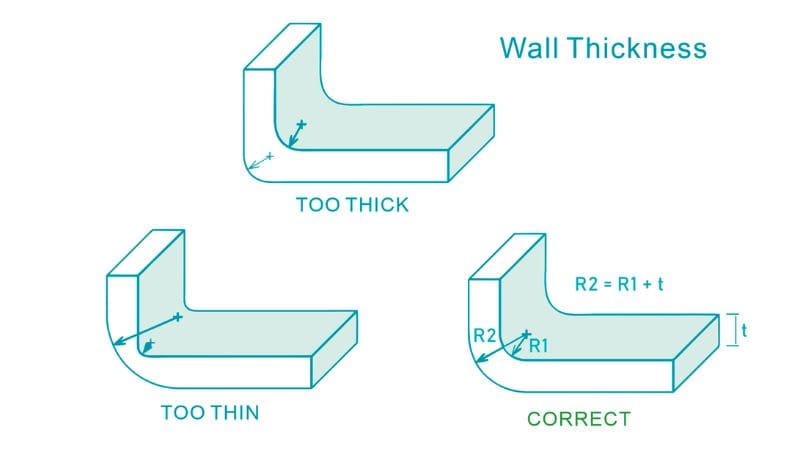

Those who do injection molding production know that the most direct way to improve efficiency is to shorten the cycle time. How can we shorten it? Engineers have figured out that reducing the wall thickness of plastic parts is a key solution – because as the wall thickness becomes thinner, the cooling time is shortened, and the entire production cycle naturally speeds up. Not only that, for plastic parts of the same size, thinner walls require less plastic, reducing production costs. Additionally, more components can be placed in the production equipment, resulting in higher space utilization.

However, it should be noted that the wall thickness cannot be reduced arbitrarily. It is necessary to ensure that the strength and toughness of the plastic parts meet the standards. For example, in daily use, they should be able to withstand slight collisions and not be easily damaged by a drop. Therefore, during the design process, it is necessary to repeatedly calculate and ensure that the mechanical performance is not a problem.

The current injection molding technology is actually quite mature, and it is not difficult to make thin-walled parts that are 1mm or even thinner. But once IMD and thin-walled injection molding are combined, a new problem arises: the thinner the wall thickness, the easier it is for the thin film at the gate position to be pulled apart. Sometimes the paint is pulled to a different position, making it look colorful; In severe cases, the colored layer on the film is directly worn off – this is also an important reason why in the past, when making IMD plastic parts, the wall thickness had to be kept at least 1.8mm.

2.2 Engineering objectives

In this cooperation, several companies set three clear goals from the beginning, all based on actual production and market demand:

- Integrated Mold Production: The top shell (with film decoration) and bottom shell (without decoration) need to be formed together in a set of “1+1” mold. Siemens has its own process for producing plastic parts, and this approach allows for the direct delivery of a complete set of casings to the assembly line, eliminating the need to produce them in two separate batches and save a lot of time.

- Compressed Production Cycle: The entire manufacturing cycle should be controlled within 10 seconds. This requirement means that every step from mold clamping, injection molding to part picking must be timed, and even the actions of automation equipment must be accurately planned.

- Accelerated Time-to-Market: This requires two aspects: first, do not delay the research and development stage for too long, and come up with mature solutions as soon as possible; The second is to use standard components for production equipment as much as possible, without the need for special customization, so that the production line can be set up quickly.

2.3 Interdisciplinary Collaboration: Multi party Enterprise Assistance

This kind of work that requires both IMD and thin-walled injection molding cannot be done by a single enterprise – it involves too many technologies, from film and ink to molds and injection molding machines, and without any link, it is impossible to play. So it is necessary to collaborate across disciplines, allowing experts from each field to play a role, and to integrate technologies such as film, silk screen ink, film manufacturing, internal mold decoration materials, injection molding machines, and automation together in order to achieve success.

Specifically, the division of labor among the five enterprises is particularly clear:

1)Siemens, the well-known brand that produces cordless phones, is responsible for the design and manufacturing of molds, as they know best what kind of casing they need.

2)Albea Plastic Technology Company in Germany specializes in the pre-processing of films, such as printing patterns on films, shaping them into three-dimensional shapes, and finally cutting them into appropriate sizes.

3)Proell from Germany focuses on ink research and development. Their internal mold decoration silk screen ink can be used for both single-layer and double-layer films, and is resistant to high temperatures without being burned out during injection molding.

4)Bayer in Germany mainly provides plastic raw materials for film and inner mold decoration, and also needs to use software to calculate how the plastic flows smoothly in the mold and how it cools evenly.

5)Engel, an Austrian company, is the “coordinator” of the entire project, not only providing injection molding machines and automation equipment, but also coordinating all aspects to ensure that everyone has a consistent pace.

3. Key Issue: Solution to Film Damage in Gate Area

The key to making “thin wall injection molding with film decoration” truly usable is to solve one problem: do not damage the thin film at the gate.

3.1 Core Issues and Investigation of Influencing Factors

In order to find a solution, engineers conducted a lot of pre experiments and tested all the factors that may affect film damage:

- The situation of the membrane itself: what material is used, whether it is a single-layer or multi-layer structure, and how thick it is.

- Details of film printing:what color to print, how many layers of color to print.

- Mold design:What is the most suitable diameter for the needle valve on the hot runner.

- The overall parameters of the plastic parts:the total wall thickness and the material used for internal mold decoration.

- Process parameters during injection molding:whether the injection speed should be faster or slower, how much pressure should be maintained, what is the temperature of the plastic melt, and how to set the mold temperature.

In order to conduct experiments, a mold was used to produce plastic parts that mimic the shape of variable thickness strips. The size of the strip is designed to correspond to the actual flow channel and volume of the membrane decorative top shell.

3.2 Experimental Conclusion and Final Solution

During the experiment, they specially made a special mold to produce plastic parts in strips with different thicknesses. The flow channels and volume were similar to the actual membrane decorative top shell to be made, so that the measured results were reliable.

After the test, two particularly important conclusions were drawn:

1)To prevent damage to the film at the sprue, it is essential to rapidly cool the film near the sprue – this is the most critical point.

2)In addition, the diameter of the hot runner needle valve also needs to be selected correctly, it cannot be too large or too small, it must be just right.

The impacts of film thickness and inner mold decoration plastic layer thickness are also significant:

1)The thicker the film, the more severe the damage. Why? Because a thick film acts like a “thermal insulation layer”. Under the same mold temperature, the temperature inside the thick film is higher, making the ink and film more likely to be damaged by heat.

2)The thinner the inner mold decoration plastic layer, the more likely the film near the gate is to be “worn off”. This is because a thinner plastic layer narrows the runner, causing the plastic to flow faster inside. The increased friction against the film naturally makes it easier for the colored layer to be worn away.

Based on these experimental results, engineers finally set the total thickness of the plastic part at 1.2mm (including the plastic layer and decorative film), and even reduced the effective runner at the film position to approximately 0.9mm. In addition, they chose PC/ABS alloy as the inner mold decoration material, and there are specific reasons for this choice:

1)The gate can be placed anywhere, no need to worry about its position;

2)The weld lines formed when the plastic converges in the mold will not appear in the key areas of the shell, which does not affect the appearance or strength;

3)The cooling runner in the mold is reasonably designed, enabling it to dissipate heat evenly without local overheating;

4)The plastic part will not deform, especially not warp due to slow heat dissipation on the film side.

4. Choose the Appropriate Automation Solution

Automation plays an important role in continuously minimizing cycle time.

4.1 Restrictions

The following restrictive conditions are in effect: the machine cycle determines the entire cycle time. So the robotic arm must be able to perform all manual operations outside the mold within the cycle time. The extremely short cycle time makes it necessary to minimize the insertion and removal time.

A high-speed processing device similar to Engel ERS can achieve acceleration with minimal driving force and high dynamic servo motors, with an acceleration of up to 150m/S2, ensuring rapid embedding of the film and rapid removal of plastic parts. The standard robotic arm (Engel ERC) is now performing some remaining work outside the mold area. This automation solution based on division of labor was chosen by Siemens Engineering. A tray is also used to manage the finished products stacked on top of the tray.

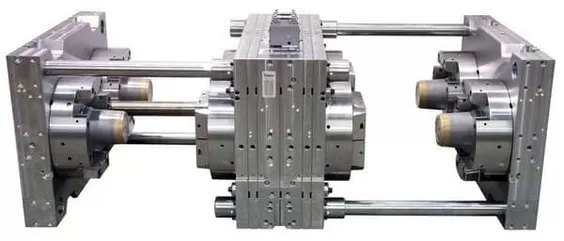

4.2 Mold technology

The design and manufacturing of molds are completed by Siemens, while Engel’s mold workshop provides support for mold decoration technology. The upper and lower parts of the phone case are injected once. The gate is a filled hot runner, and each plastic part has two pneumatic needle valves. The top shell decorative film is inserted into the movable half mold, so the ejection structure is also placed on the fixed side.

The top shell with film decoration and the bottom shell without decoration have different requirements for process control, and they are in the same mold. For example, consider the different temperature controls required for moving the half mold: although the mold inserts adapted to the film must be rapidly cooled, in order to ensure high-quality non decorative bottom shell surfaces, a mold temperature of 40-50 ℃ is required.

4.3 Film

A film composed of PC/PBT alloy is used in Gigaset 4000 with a double-layer structure (including a total thickness of approximately 300mm for printing ink). The basic characteristics of this decorative film are:

1)Uniform surface;

2)High chemical resistance;

3)When HPF deforms (due to high pressure cold forming caused by temperature below the softening point of the membrane and excessive pressure, as well as maintaining the surface structure), it has good deformation ability.

The silk screen ink developed specifically for internal mold decoration technology is known for its good adhesion, deformation ability, and excellent heat resistance and shear performance in injection molding. In addition to the base color, the color range also includes special metallic and effect pigments (such as color changing or pearl effect). Albea is responsible for forming and trimming the film.

4.4 Interior Decorative Material

The interior decorative material used in this application is PC/ABS alloy. It meets the high material requirements for the combination of internal mold decoration and thin-walled injection molding, such as:

- Good flowability;

- High level mechanical performance;

- Heat resistance;

- Excellent adhesion to thin films;

- The processing window is large.

4.5 Production Unit

The core of the production unit is Victory200/120 Tech (120 ton locking force) produced by Engel. Even the basic models in the standard system of this series of elbow free injection molding machines can meet high requirements for accuracy, repeatability, and economy: the entire cycle time of about 8 seconds exceeds the target value of the project.

Here is an overview of the processing procedure: The linear robotic arm (Engel ERC) takes the film out of the stack and moves it to the middle stack in front of the predetermined center position. Its contour is a complete replica of the mold cavity. The reserved heart position can also serve as an interface for transmitting to high-speed processing devices (Engel ERS). The linear robotic arm grabs two shells and transfers them onto the tray. At the same time, the high-speed processing device has sent the film to the waiting position in front of the still closed mold. When opening the mold, the transfer head crosses into the mold area, inserts the film into the closed end half mold, and uses the other end to simultaneously take out the finished product from the fixed half mold. The centering device inside the mold ensures that the relative position between the embedded head and the mold cavity is always accurate, as the precise fit between the film and the mold cavity is crucial for quality.

The production factory operates with extremely high repeatability: assuming a 16g component, the maximum weight difference is ± 0.065%. This is unusual for interior decorative components, as this value also includes changes in the weight of the film (including printing layers and punching deviations).

IMD technology specific inks include Germany’s Baolong HTR, N2K, PCI, NORIPET, NORICRYL, AQUEPRESS, NORIPRESS, etc.

If you have further exploration needs for the new process combining IMD and thin-walled injection molding, or hope to cooperate with KingStar for one-stop manufacturing solutions, please feel free to contact us by email (sales@kingstarmold.com) or fill out a from on our contact page.