Custom Plastic and Metal Parts Production Services

KingStar Mold offers a seamless, one-stop service for customizing plastic and metal parts. With a complete range of equipment and processes, we eliminate the hassle of coordinating with multiple companies for different production steps.

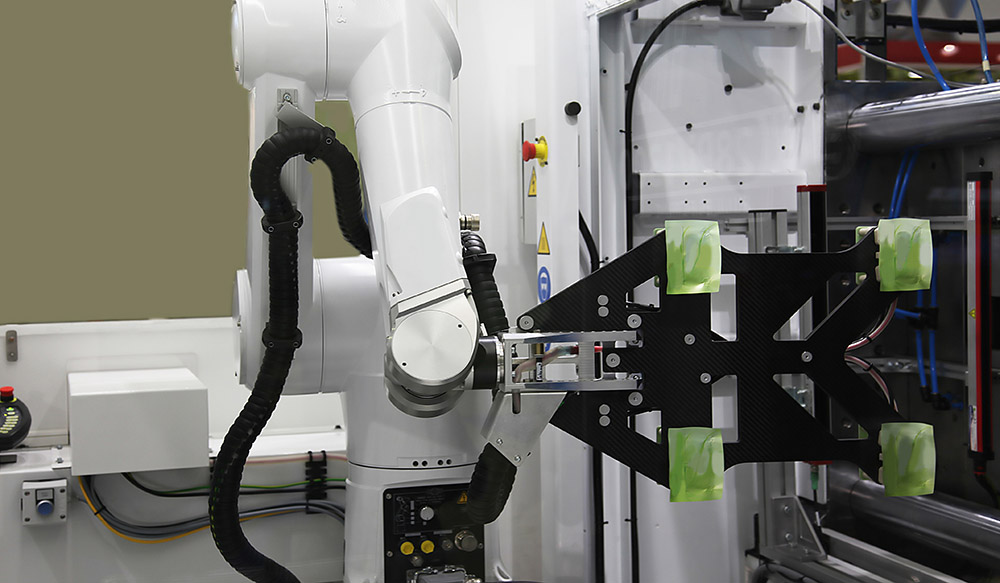

Injection Molding

KingStar Mold offers injection molding solutions, including design, mold making, production, and surface finishes.

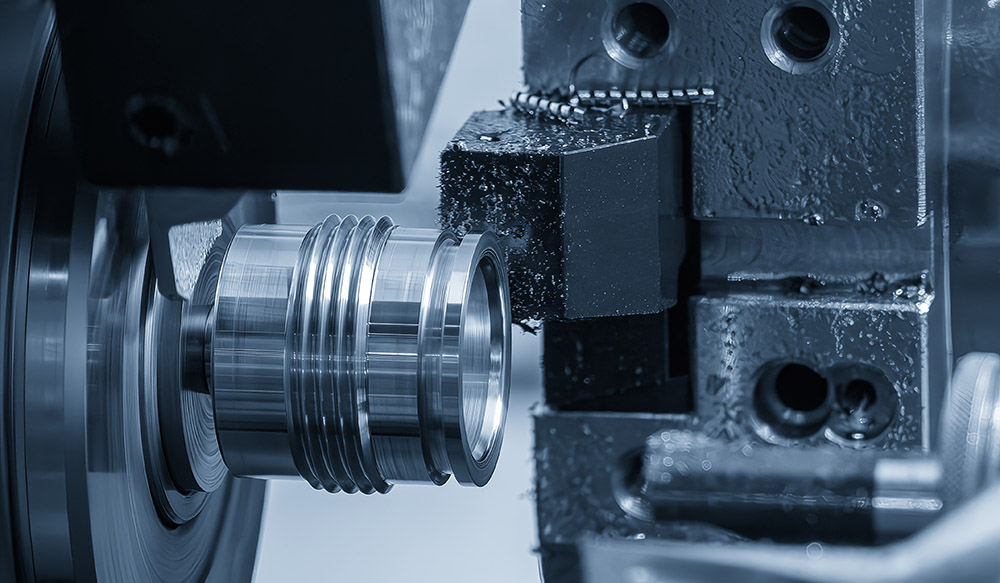

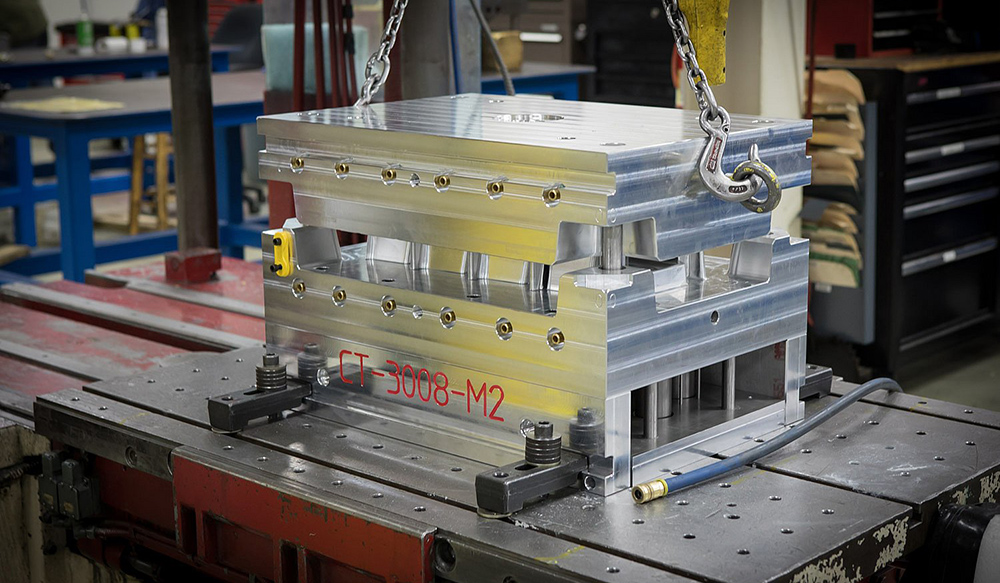

Mold Making

KingStar Mold uses CNC cutting and EDM machines to create molds, offering free design and material advice.

Who We Are

Custom Manufacturing & Precision Machining Company

KingStar Mold is a national high-tech digital manufacturing company specializing in custom parts. We produce precision plastic and metal parts, as well as ODM products, using advanced techniques like precision molds, injection molding, rapid prototyping, and CNC machining. Our products serve diverse industries, including automotive, aerospace, medical devices, and consumer electronics.

30+

Served Countries

KingStar Mold has built a strong global presence in over 30 countries, including the United States, Germany, Japan, the United Kingdom, and more.

120+

Technical Personnel

Our team is composed of skilled professionals across departments, including engineering, mold design, quality control, and project management.

110+

Professional Equipment

We utilize advanced machinery from top global manufacturers to enhance our production capabilities, ensuring precision and high-quality results.

10+

Years of Experience

With over a decade of experience, KingStar Mold continues to lead in manufacturing innovation, providing consistent quality and reliability.

Why Choose Us

Reliable Molding Factory

Only companies with extensive market experience and a deep understanding of customer needs can offer the best service.

Skilled

High-precision production equipment, skilled production staff, and guaranteed delivery times.

Experienced

Over ten years of industry experience, with a mature quotation system and technical support.

Thoughtful

Customized processing options that save time and effort, with active support throughout pre-sales and post-sales.

Equipped

Engineers review designs to identify and resolve potential issues, backed by advanced testing equipment.

Robust Organization Paired with Advanced Processing Equipment

Injection department, CNC processing department, quality control department, mold department, marketing department, sales department, logistics department, purchasing department, PMC.

KingStar Mold at a Glance

KingStar Mold envisions long-term growth, attracting top talent and embracing flexible strategies for innovation.

Diverse and Skilled Workforce

30,000㎡ Factory

Global Business Expansion

KingStar Mold takes pride in collaborating closely with our clients, offering valuable insights, innovative ideas for improved products, and approachable, customer-focused service that stems from our commitment as a global high-tech manufacturing leader.