Core in 4-Axis & 5-Axis CNC Machining

By adding one or two rotational axes to the worktable, 4-Axis and 5-Axis machining enhances our machines’ ability to handle more complex and detailed parts. At KingStar Mold, we recognize that the true advantage of 4-Axis and 5-Axis machining comes down to three crucial elements: precision, efficiency, and cost-effectiveness.

While many machining facilities use 4-Axis and 5-Axis CNC technology, KingStar Mold stands out by optimizing these capabilities to their fullest potential, ensuring the highest levels of precision, productivity, and cost control. This is made possible by our skilled team and our highly efficient production management.

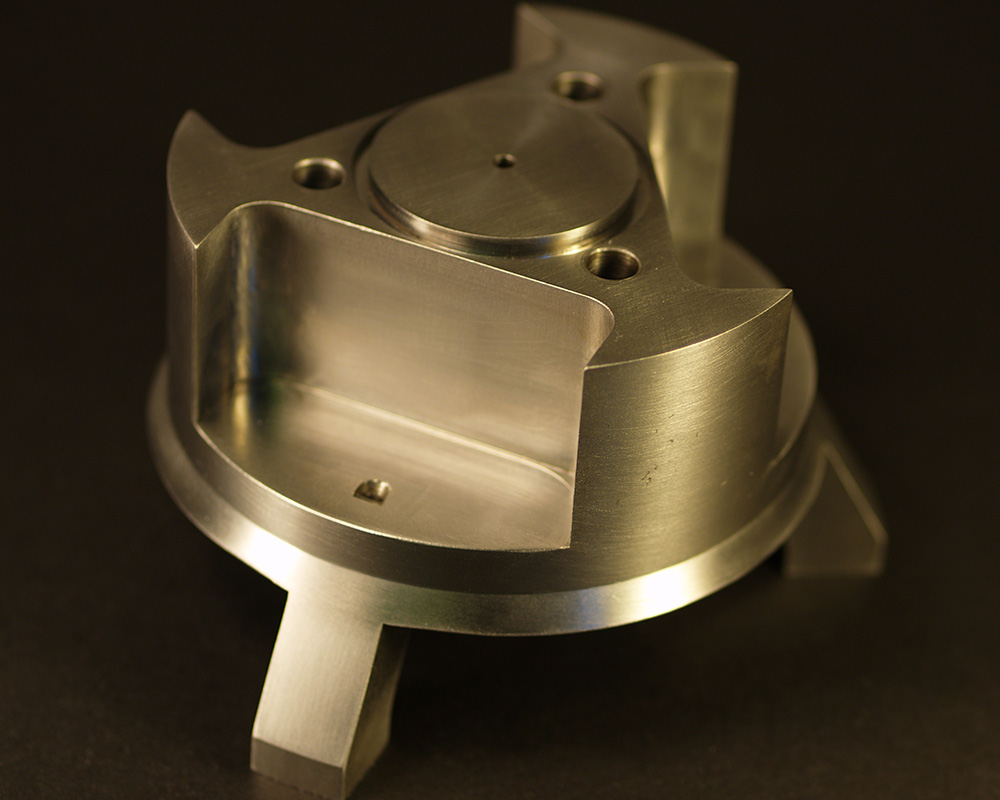

4-Axis and 5-Axis CNC Machined Part Gallery

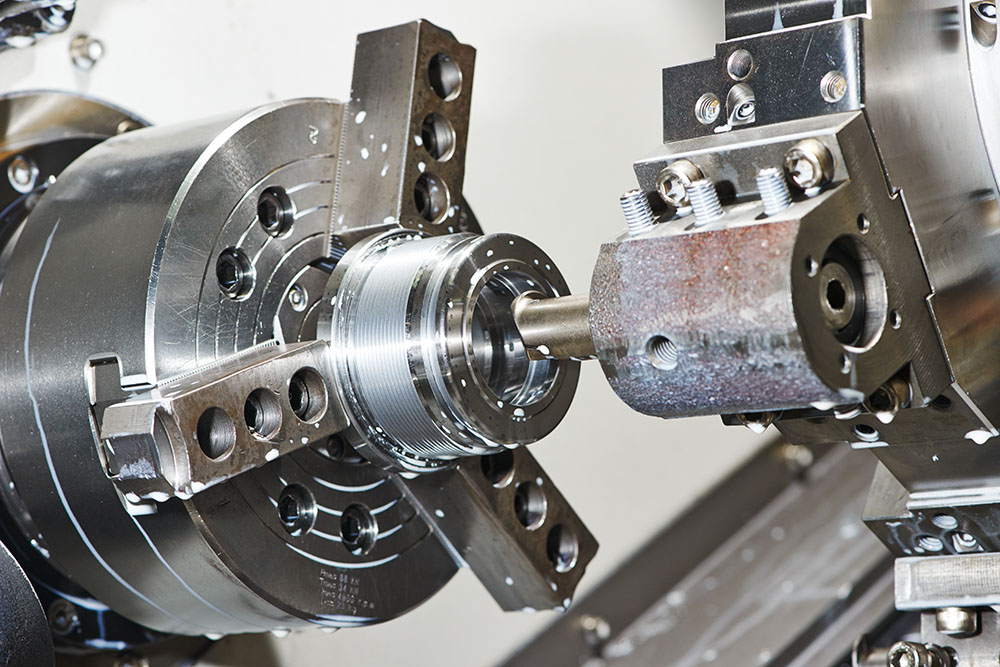

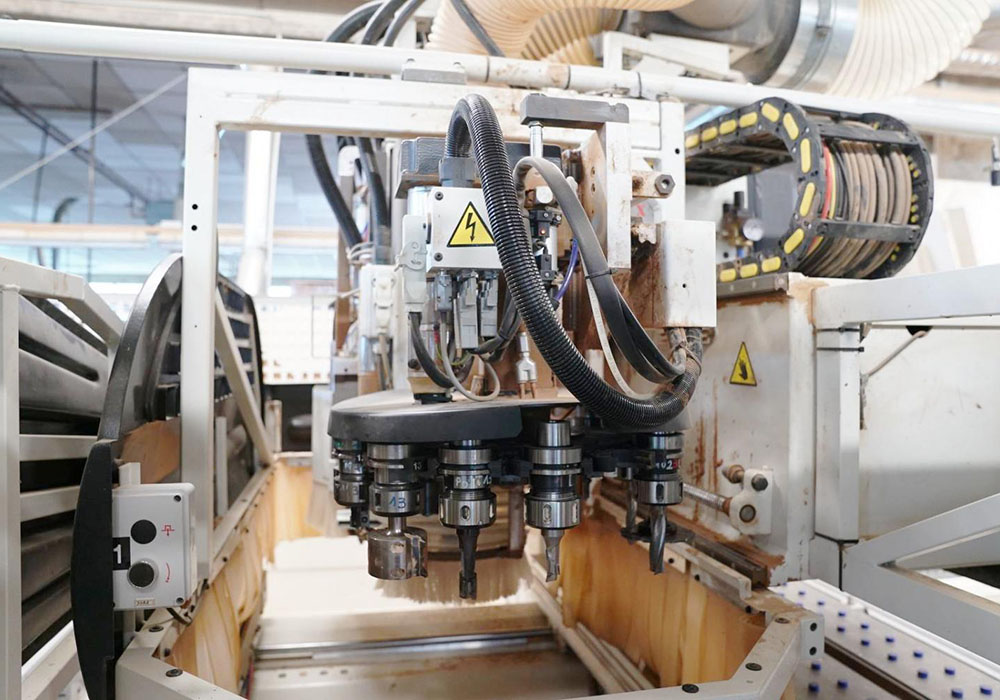

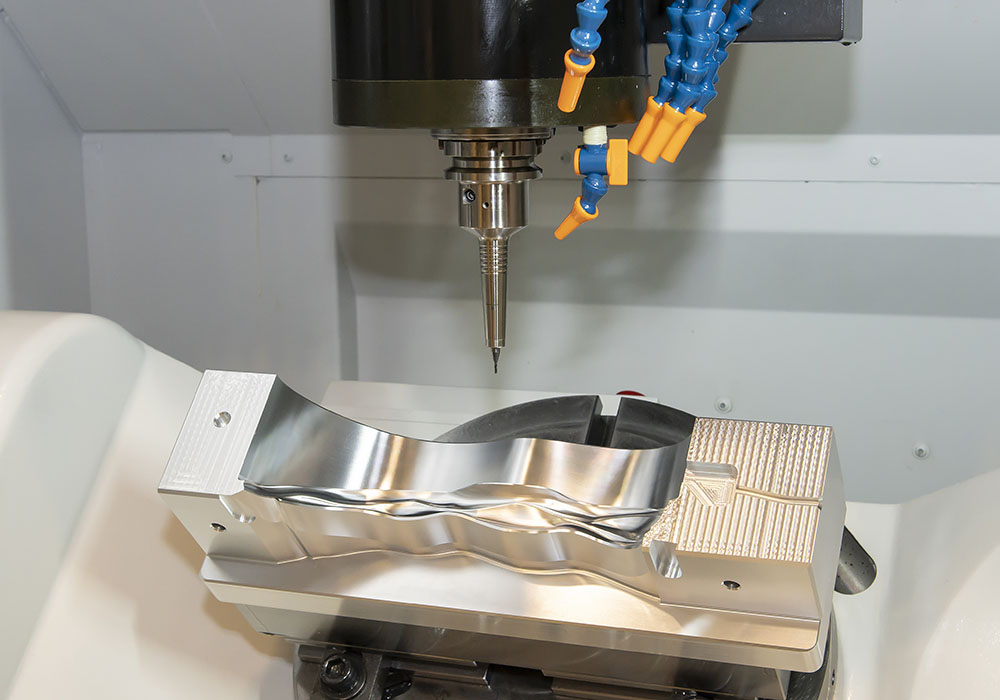

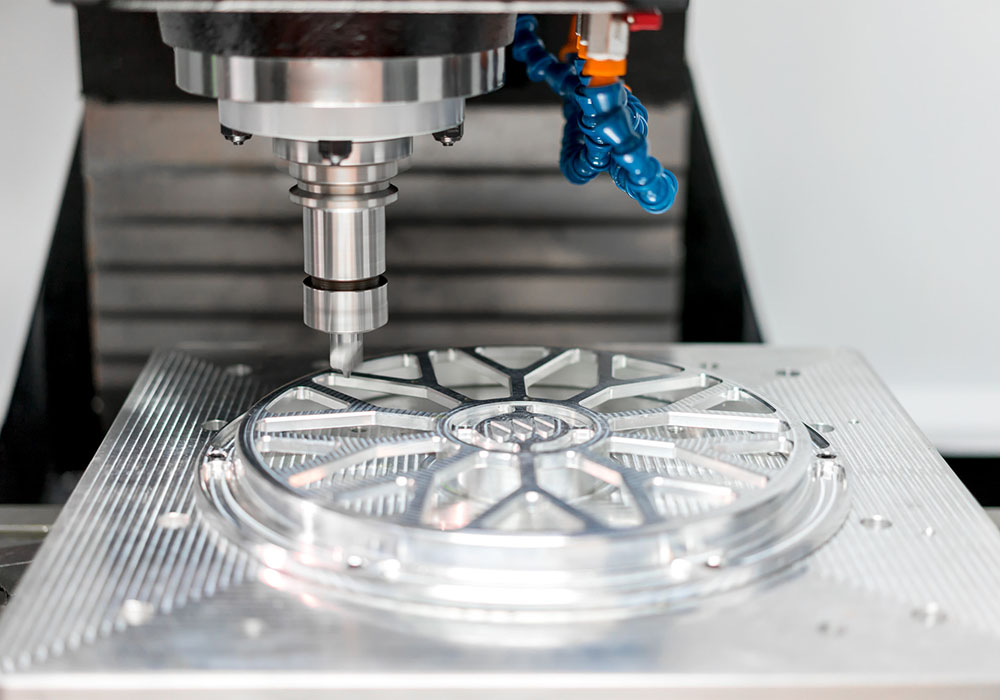

Both 4-axis and 5-axis CNC machining are advanced multi-axis machining processes that enable the creation of highly complex parts. These processes are capable of machining a wide variety of shapes with precision, offering flexibility and efficiency for a range of manufacturing needs.

Precision Measurement for 4-Axis and 5-Axis CNC Machined Parts

The following table outlines our recommended tolerance standards for CNC machining. If you do not have specific tolerance requirements for your part, we will proceed using the standard class. Additionally, our team will reach out to you promptly to review your product and suggest the most appropriate tolerances based on our experience.

| Tolerance Type | Tolerance Range | Application | Description |

|---|---|---|---|

| Geometric Tolerance | ± 0.005 mm to ± 0.05 mm | Precision parts requiring high form control | Controls the shape, orientation, and position of features to ensure part accuracy. |

| Linear Tolerance | ± 0.001 mm to ± 0.1 mm | General CNC machining | Defines the permissible variation in linear dimensions for mechanical parts. |

| Angular Tolerance | ± 0.1° to ± 1° | Parts with specific angular features | Specifies the allowable deviation in the angle between two surfaces or axes. |

| Surface Finish | Ra 0.8 to Ra 1.6 | Parts requiring smooth surface finish | Defines the roughness of the surface to ensure fit, function, and aesthetics. |

| Position Tolerance | ± 0.01 mm to ± 0.1 mm | Parts with holes or features that require precise location | Specifies the allowable variation in the position of features relative to a datum. |

| Concentricity Tolerance | ± 0.01 mm to ± 0.05 mm | Rotating or symmetrical parts | Ensures that two or more features, such as holes or shafts, are centered within one another. |

| Circular Runout | ± 0.01 mm to ± 0.1 mm | Rotating parts like gears or shafts | Measures the variation in the circularity of a feature as it rotates around its axis. |

| Flatness Tolerance | ± 0.01 mm to ± 0.1 mm | Parts requiring flat surfaces for assembly or function | Controls the deviation from a perfectly flat surface within specified limits. |

The accuracy of 4-Axis and 5-Axis CNC machines can be extremely high, with tolerances often achievable down to ±0.01 mm or better, depending on the machine, material, and complexity of the part. At KingStar Mold, we prioritize precision to ensure the parts meet your exact specifications.

5-Axis machining offers several advantages over traditional 3-Axis CNC machining, including the ability to machine more complex shapes in a single setup, reduced setup times, improved accuracy, and the ability to work on multiple sides of a part without repositioning. This leads to more efficient production and higher-quality finished parts.

KingStar Mold stands out for its commitment to precision, efficiency, and cost-effectiveness. We leverage advanced 4-Axis and 5-Axis CNC technology to produce highly intricate parts with tight tolerances. Our skilled team and optimized production processes ensure that every project is completed to the highest standard, on time, and within budget.

5-Axis CNC machining expands upon the capabilities of 4-Axis machining by adding one more rotational axis (typically the B-axis). This enables the tool to access virtually any surface of a part, allowing for even greater precision and complexity. It’s ideal for complex, detailed parts such as aerospace components, medical devices, and molds.

4-Axis CNC machining refers to a process where the tool is able to move in three linear directions (X, Y, Z) as well as rotate around one axis (usually the A-axis). This added rotation allows for more complex part geometries, making it ideal for parts that require undercuts or rotational symmetry.

KingStar Mold differentiates itself by offering advanced CNC machining capabilities combined with a customer-first approach. We optimize our processes to provide the highest precision, efficiency, and cost control, ensuring your projects are completed on time and to the highest standards. Our experienced team is dedicated to delivering custom solutions tailored to your specific needs.

The time it takes to machine a part depends on several factors, including the complexity of the design, material, and desired tolerances. While 5-Axis machining can sometimes take longer than traditional 3-Axis, the reduced need for multiple setups often leads to faster overall production times for complex parts.

Several industries benefit from 4-Axis and 5-Axis CNC machining, including aerospace, automotive, medical, defense, consumer electronics, and mold-making. These industries require parts with complex geometries, tight tolerances, and high-performance standards, making 4-Axis and 5-Axis machining an ideal choice.

KingStar Mold maintains rigorous quality control standards throughout the machining process. We use state-of-the-art inspection equipment, including CMM (Coordinate Measuring Machines) and advanced software, to ensure every part meets the required specifications. Our quality assurance team verifies tolerances at every stage of production.

Yes! KingStar Mold specializes in rapid prototyping and can efficiently produce prototypes using both 4-Axis and 5-Axis CNC machining. Whether you need a single prototype or a small batch, our capabilities allow us to bring your designs to life quickly and accurately, helping you refine your product before mass production.

4-Axis and 5-Axis CNC machining are ideal for parts with complex geometries, such as mold components, aerospace parts, medical devices, automotive parts, and custom tooling. These processes excel in creating parts with intricate details that require multi-angle machining or high precision.